Electrochemical Method of Tungsten Bronze Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 11 April 2016 18:40

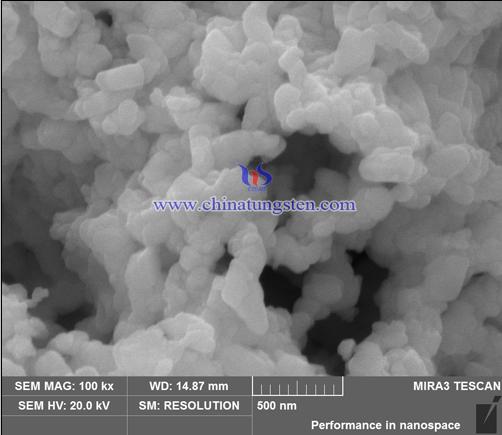

It’s the most common method to prepare tungsten bronzes, especially hydrogen tungsten bronze and lithium tungsten bronze, and reactions of the preparation are the basic reaction of these two kinds of the tungsten bronze applications. Electrochemical preparation of tungsten bronze does not require high temperature, and it’s easy to get good crystals. The preparation process is as follows: First, according to a certain method to make WO3 electrodes, then WO3 as cathode, inerts like graphite, Pt lithium thin electrode as the anode, electrolysis in sulfuric acid, nitric acid or the corresponding lithium salt, hydrogen tungsten bronze and lithium tungsten bronze can be obtained. WO3 has a great influence on the reaction (including current and reaction products), and it was considered to be due to the reaction process requires WO3 corresponding form changes.

Schasche and Schollhorn electrolysis pressed hexahedral WO3 electrode in 0.05mol / L H2SO4 solution , and prepared hexagonal H0.6WO3 with the unit cell parameters a = 0.7597nm, c = 0.7567nm. Amorphous WO3 films was also used as an electrode to prepare the HxWO3, and studied thermodynamics, optical and conductive properties.

Electrochemical Preparation of LixWO3 has been reported in the early 1980s, the study of structural changes during the preparation has begun since the early 1990s. Respectively WO3 powders and WO3 polycrystalline deposited thin film as the cathodes, lithium thin as anode, comprising an amount of 1: 1 vinyl LiClO4 electrolytic reaction solution carbonate and propylene carbonate in. The results showed that the tetragonal Li0.1WO3 and hexagonal Li0.36WO3, wherein the x value of hexagonal lithium tungsten bronze can be up to 0.5, and the reaction to a particular crystalline WO3 is reversible.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com