Tungsten Carbide Mixture Wet Milling-spray Drying (1/2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 March 2016 15:10

Tungsten carbide is basically composed of WC and Co, which has high hardness, high strength, high wear resistance and excellent chemical stability and can be widely used in various cutting tools, drilling tools and so on. Now tungsten carbide has been a new development in the field of electronics as well as some in the medical field, such as PCB micro drills and drills for dental, which place a greater demand on tungsten carbide properties. Therefore, viewed from the raw material, high quality of tungsten carbide products is determined by tungsten carbide mixture. If the mixture has poor quality, even though the process and equipments are advanced, the final products can not be well. Currently, there are two preparation of domestic carbide mixture, one is wet milling-machinery granulation process, the other is wet milling - spray drying process.

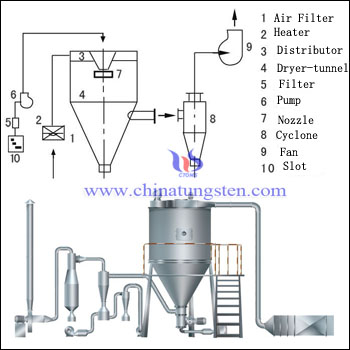

Wet milling-machinery granulation process has simple equipment and operations, but the drying and granulation should be divided into two parts so that it needs a long time and the mixture will be oxidized by contacted with the air or other impurities. Although tungsten carbide mixture wet milling-spray drying equipment is more complex, pre-investment is relatively high, its high level of automation of production, produce a better blend of mobility, uniform particle size distribution, bulk density stable and be able to meet the production needs of high-volume, high-performance tungsten carbide products. Compared with conventional wet milling-machinery granulation, the basic process of wet milling-spray drying is preparation → wet milling → spray drying → the mixture, which takes place of vacuum drying, rubbing sieve, granulation and many steps and remarkably improves the overall efficiency.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com