SCR Denitration Catalyst Raw Material – Tungsten Trioxide 1/2

- Details

- Category: Tungsten Information

- Published on Friday, 18 March 2016 18:51

SCR denitration catalyst mainly refers to the catalyst used in powder plants system; the chemical which is prompting substance selectively reducing with nitrogen oxides in the flue gas at a certain temperature in the SCR reaction. The main raw materials of SCR denitration catalyst including precious metals and metal oxides, in which the primary precious metals Pt, Pd, Rh and Ag are being as the catalyst; therefore, the metal oxides are V2O5, WO3, MgO and NiO ect.. Among them, WO3 takes the role of anti-oxidation, anti-drug. With the in-depth study of the SCR denitration catalyst, precious metal is replaced soon by metal oxide catalyst, because of its high cost. Today, V2O5/TiO2, V2O5-WO3/TiO2 or V2O5-WO3/TiO2which have high catalytic activity, are widely used in traditional SCR denitration apparatus.

According to the different raw materials, SCR denitration catalyst can be divided into platinum, titanium, V and hybrid series. Platinum catalysts, being the first catalyst put into use, is eliminated because of its high cost and harsh require in ash.

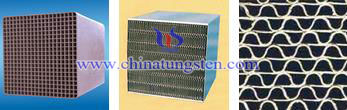

SCR denitration catalyst mostly with active ingredient covering at the surface, wherein vanadium (V) takes the main component of active ingredient, WO3 is being as the auxiliary component. The SCR denitration catalyst is made by taking the glass fiber and titanium dioxide as carriers, molding by cutting, assembling and calcination, then mixing carrier active ingredients well by rolling-sided method. Currently, there are three mainstream denitration catalyst structures in the market, respectively cellular, plate and corrugated board.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |