Excellent Properties of TIG Welding

- Details

- Category: Tungsten Information

- Published on Monday, 07 March 2016 17:43

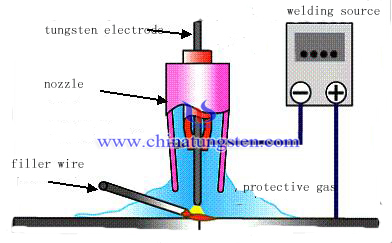

TIG welding has a lot of excellent properties.

1. TIG welding often uses argon as a protective gas. Argon arcs easy and stable. In addition, the density of argon is large, in the welding process can form a good protective cover, playing a good protection. And argon has large atomic mass, having a good cleaning cathode effect.

2. High weld quality, during welding process, argon gas does not react with the metal and not dissolved in the metal as well, so the whole welding process is simple main metal melting and crystallization processes, which is possible to obtain a high purity and quality welds.

3. Little welding deformation and stress, effecting by argon stream compression and cooling the arc heat is concentration, heat-affected zone very narrow, so the welding deformation and stress are small, which is suitable for sheet metal welding.

4. Easy to observation and operation, TIG welding is kind of open arc welding, so it is easy to observe, easy to operate, and suitable for all position welding.

5. Wide welding range, almost all metal materials can be welding, especially for welding lively chemical properties metals and alloys, such as aluminum, magnesium, titanium and other metals.

6. Stable arcing, TIG welding has stability current, and even in a small welding current can still stable combustion, which is suitable for thin plate materials producing.

TIG welding not only has large welding range, but also has high quality welding and can obtain high quality welds, so it is widely used in the industrial. With the development of science and technology, it is also often used as bottom welding for carbon steel and low alloy steel pressure pipe to improve the quality of welded joints.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |