Bismuth Oxide Influencing Tungsten Trioxide Ceramic Property

- Details

- Category: Tungsten Information

- Published on Monday, 15 February 2016 17:16

When the doping concentration is 0.2mol% and the sintering temperature is about 1100 ℃, the density of the WO3 ceramics doped Bi2O3 can reach 91%. When the doping concentration is 0.2mol% , WO3 ceramics densification will decline; the sintering temperature is lower than 1100 ℃, the density increases gradually, but when the sintering temperature is 1100 or higher than 1100 ℃, the density of the ceramic will decline ; the best sintering time is 2h, extend the time will make the ceramics sintered density decreases. After analysis, the major causes for this phenomenon are: WO3 melting point is 1273 ℃, Bi2O3 melting point is 860 ℃, the formation of the sublimation are the two substances .

When the doping concentration is 0.2mol% and the sintering temperature is about 1100 ℃, the density of the WO3 ceramics doped Bi2O3 can reach 91%. When the doping concentration is 0.2mol% , WO3 ceramics densification will decline; the sintering temperature is lower than 1100 ℃, the density increases gradually, but when the sintering temperature is 1100 or higher than 1100 ℃, the density of the ceramic will decline ; the best sintering time is 2h, extend the time will make the ceramics sintered density decreases. After analysis, the major causes for this phenomenon are: WO3 melting point is 1273 ℃, Bi2O3 melting point is 860 ℃, the formation of the sublimation are the two substances .

Comparing with non-doped WO3 ceramics, WO3 ceramics doped Bi2O3 varistor voltage declines rapidly, this shows the rapid growth of the ceramic grains causing breakdown voltage drop. When the sintering temperature of WO3 doped Bi2O3 ceramics is 900 ℃, WO3 ceramics do not have pressure-sensitive properties, when the temperature is 900 ℃ ~ 1100 ℃, the pressure-sensitive is maximum coefficient, when the sintering temperature is 1100 ℃, the pressure-sensitive decreases with the temperature rises, it disappears after sintering temperature is higher than 1100 ℃. When Bi2O3 doping concentration is 0.5mol%, the sintering time is 2h.

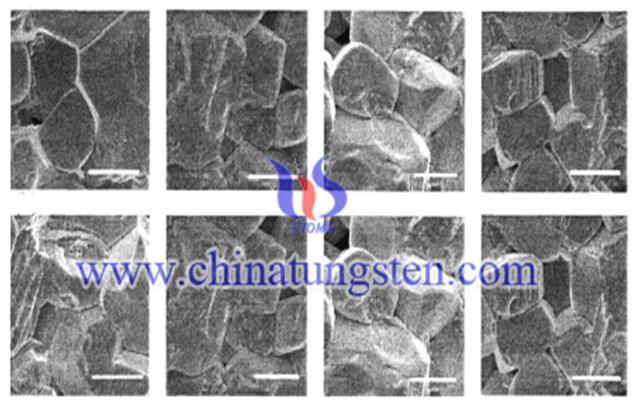

Doping Bi2O3 having a significant effect on the microstructure of WO3 ceramics; doping can play a role to help promote sintering ceramics; doping can improve the characteristics of the ceramic varistor.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |