Methods for Dealing with W-Mo Slag in Ammonium Paratungstate Production

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 January 2016 17:09

High-quality tungsten mine is becoming less due to the continuing exploitation of tungsten resources in recent years, and tungsten ore with high content of molybdenum will be the main raw material of tungsten metallurgy, this would be bound to bring great negative. With the rising price of tungsten and molybdenum products, reasonable comprehensive use W-Mo Slag generated in the production of ammonium paratungstate (APT), not only can create profits to enterprise resource reuse, but also create wealth for the country.

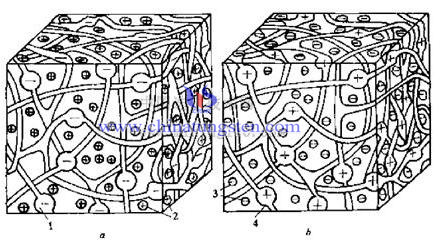

The methods for dealing with the sulfided W-Mo Slag in APT production process at present are as follows:

1. Sell to molybdenum manufacturers in the form of deputy products for single recovery, this method will do no good to tungsten reuse to a large extent;

2. The sulfided molybdenum slag return to ball grounding process to accompany with the tungsten concentrates material.

The disadvantage of this method is:

1) Increase the treatment cost of ball grounding and ion exchange process, the content of tungsten in the slag can not be controlled effectively;

2) A large amount of impurities elements in the molybdenum slag will damage to the resin in ion exchange process thus easily cause resin poisoning, and bring larger economic loss;

3) It is not conducive to effective recycling molybdenum because large number it leaved in tungsten slag and dealt as waste;

4) Increase the labor intensity of workers.

3. Dissolve sulfided W-Mo slag generated in APT production into ammonia, inlet water vapor into pot made by titanium crystal, filtering and cooling after reaction, sulfide the filtrate for removing molybdenum, and qualified APT and slag containing with molybdenum obtained.

The advantages of this method lie in:

1) Effective use of resources and reduce the environmental pollution of ammonia;

2) Enrich molybdenum effectively and provide a good raw material for downstream industries, thus make full use of valuable resources.

| APT Supplier: Chinatungsten Online ammonium-paratungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |