Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 January 2016 17:32

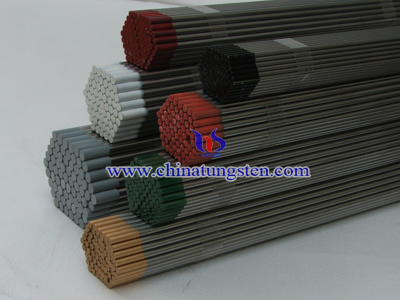

Tungsten electrode having good electron emission ability, high melting point, high elastic modulus, low vapor pressure, low temperature creep, high strength, resistance to burning, high recrystallization temperature and other good performance is often used as high thermal electron emission materials. Tungsten electrode is mainly used in the inert gas welding, plasma cutting, spraying and smelting and it is essential materials for machinery, shipbuilding, aerospace, construction, nuclear power, metallurgy and other fields. Tungsten electrode is not used for direct soldering, and are widely used in AC welding. It is generally used for welding aluminum and magnesium alloy, providing a good stable arc sine wave in the welding process, so it is widely used in various fields specific welding applications.

However, due to tungsten electrode has a very high electron work function, thus arcing and maintaining the stability of the arc is difficult. In addition, it has low emission efficiency. Besides, at a high temperature it is easy recrystallization to form equiaxed grain structure leads to electrodes rattle, which greatly limits the use of tungsten electrodes.

In order to overcome these shortcomings, after study found, adding rare earth oxides having low electron into tungsten-base electrode can improve the recrystallization temperature of the tungsten electrodes and can activate electron emission as well, so that the tungsten electrode welding performance can be improved, expanded the application fields of the alloy. Adding rare earth oxides of tungsten-based alloy has better arcing performance, higher stability of the arc column, and electrode burning rate becomes smaller. Currently, common rare earth oxide additives are cerium oxide, lanthanum oxide, zirconium oxide, yttrium oxide, thorium oxide and so on.

With the development of economy and technology, the world’s tungsten electrode consumption reached 1,600 tons per year or more. Chinese annual output of tungsten electrodes are gradually growing every year, accounting for 3/4 of the world's annual production of tungsten electrodes.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |