Electrophoretic Deposition Tungsten Trioxide Thin Film

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 January 2016 13:49

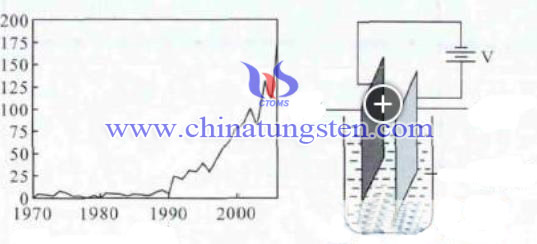

WO3 thin film renders color by irradiation with light or by using an appropriate electric field energy that referred to as a photochromic or electrochromic, which has potential applications in smart windows, large area displays and automotive mirrors, etc. Preparations of WO3 thin films are electrophoretic deposition magnetron sputtering, chemical vapor deposition, and sol - gel method.

Electrophoretic deposition refers to a stable suspension by the action of the electric field, the colloidal particles deposited material called electrophoretic deposition process. E.g., DC voltage is applied to the electrodeposition coating, and charged paint particles move to the cathode, and the cathode surface with an alkaline effect is produced by the formation of insoluble material deposited on the work surface. There are two processes on accordingly electrophoretic deposition comprises, one is electrophoresis, and the second is deposition. Entire electrophoretic deposition process is divided into the following four steps:

Electrophoretic deposition refers to a stable suspension by the action of the electric field, the colloidal particles deposited material called electrophoretic deposition process. E.g., DC voltage is applied to the electrodeposition coating, and charged paint particles move to the cathode, and the cathode surface with an alkaline effect is produced by the formation of insoluble material deposited on the work surface. There are two processes on accordingly electrophoretic deposition comprises, one is electrophoresis, and the second is deposition. Entire electrophoretic deposition process is divided into the following four steps:

(1) Electrolytic: initially, producing hydrogen and hydroxyl ions OH is the reaction at the cathode electrolysis reaction, the reaction resulting in the formation of an overbased cathode surface boundary is layer, when the effect of the cation and the hydroxide becomes water-insoluble substances, it coating film deposition:

(2) Electrophoresis: the cationic resin and H + in the electric field moves to the cathode, and anions to the anode movement;

(3) Electrodeposition: the surface to be coated, a cationic resin and the surface of the cathode basic acting, and not precipitated sediment deposited on the workpiece.

(4)Electro-osmosis: thin film coating on the surface of the solid and translucency with the majority of the pores leaking water that is discharged from the cathode coating thin film in the electric field, which causing the coating dehydration. Tu film is adsorbed on the surface, completing the electrophoresis process.

Dissolving amount of tungsten powder with hydrogen peroxide (H2O2), to prevent bumping solution, H2O2 should be added and dissolved during stirring constantly. After cooling and filtering completely, adding the appropriate amount of concentrated sulfuric acid (CH3CH2OH) and acetic acid in the filter solution (CH3COOH), which can get WO3 sol. Electrophoretic deposition is conducted under greenhouse, and the current density is DC steady flow instrument, preparing WO3 thin films from taking the substrate as an electrode, the current passing through the cathode that can be deposited WO3 thin film, which can obtaining the deposition required thickness, simple operation, a film-forming, high transparency, film uniformity and the substrate with a solid advantage.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |