New Types, Structure of Coated Cemented Carbide—Diamond Coating 3/3

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 17:20

The test of diamond coating properties is as important as the deposition. The main part of the test includes the grain size of diamond coating, another is the binding force of diamond coating and tungsten carbide matrix.

Theoretically, diamond coating has crystalline structure, the coarseness is mainly determined by the size of grain (smaller granularity, lower coarseness of surface). For tungsten carbide drawing die, the coarseness of surface plays an important role in the comprehensive properties. In the diamond coating applied to the graphite tooling tests show that when the grain size is less than 1μm, the surface roughness of <1μm, and the roughness of the workpiece conventional diamond coating is greater than 2-3μm, and operates in a workpiece using prone to particle shedding. In addition, diamond coating can combine micro particle with ultra nano particle, which can be observed clearly by SEM. This combination can be more suitable for tungsten carbide drawing die with high demand and high performance.

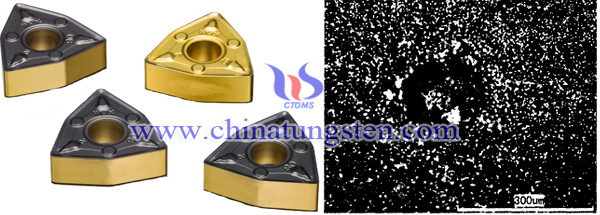

The other is the test of the binding force between diamond coating and tungsten carbide matrix. The binding force between diamond coating and tungsten carbide matrix is the foundation of the drawing work, if the binding strength is lower, diamond coating will drop off in the processing of some wire with high strength drawing, which make the mold become invalid. The binding force is adapted by diamond indentation tester, it uses diamond indenter to press the surface of diamond coating layer, the image as follow:

Viewed from the indentation of diamond coating, we can more clearly see the diamond coating cracked or peeling around the indentation does not occur, the central portion of the diamond indentation remains firmly bonded carbide coating surface of the test, followed by the pressure applied to 1.5KN, diamond coating is damage. Compared with traditional diamond coating has maximum load lower than 600N, the coating by chemical vapor deposition (CVD) can remarkably improved.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com