Waste Tungsten-Nickel Catalyst Preparing Sodium Tungstate 1/2

- Details

- Category: Tungsten Information

- Published on Monday, 11 January 2016 19:11

Tungsten is a kind of infusible and rare metal. China’s tungsten resources have significant superiority in the world. Although China's tungsten reserves, production and foreign trade exports are the first in the world at present, the situation of China's tungsten resources can’t be blindly optimistic. Tungsten resources which are available for exploiting in China are sharply reducing. Tungsten resources are facing a severe situation.

For this problem, many experts have studied the countermeasures. Recycling and efficiently using tungsten secondary resources is one of the important measures to make up for a lack of original tungsten resources. Waste tungsten - nickel hydrogenation catalyst is a kind of important marketable secondary resources. Realizing valuable metals recycling of waste tungsten - nickel hydrogenation catalyst, not only can reduce environmental pollution, increase the recycling of resources, but also can reduce the production cost of enterprises and improve the economic benefit.

This article introduces a kind of method of using waste tungsten - nickel catalyst to prepare sodium tungstate. Researchers using waste tungsten - nickel hydrogenation catalyst as raw materials, chemical metallurgy method, and according to the process principle of ion exchange method with leaching liquid, design the secondary resource recycling plan of tungsten to provide a reference for the industrial production practice. The process can be divided into the following steps:

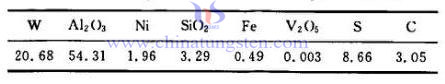

1. Waste tungsten - nickel hydrogenation catalyst contains high sulfur and organic compounds, so it must be removed oil by oxidation to let the carbon and sulfur removal rate reach 99%.

2. Mix the waste catalyst with sodium carbonate. Leach with hot water after a period of time of sodium modifying and roasting. Most of the tungsten oxides go into solution after transforming sodium tungstate. Nickel, iron oxides remain in the residue.

3. After acid leaching, residue is removed nickel, iron and aluminum, then alkali leach by sodium carbonate. The filtrate merges into the main process and the silicon residue can be directly landfill at this time.

4. The leaching filtrate through ion exchange adsorption, desorption, the high concentration of sodium tungstate solution can be got. Sodium tungstate can be obtained by crystallization and recrystallization.

| Sodium Tungstate Supplier: Chinatungsten sodium-tungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com