Doping Tungsten Trioxide Gas Sensing Properties Study

- Details

- Category: Tungsten Information

- Published on Monday, 11 January 2016 18:07

The gas sensor is a sensitive device that can be capable of sensing the concentration of the gas in environment. It can convert into electrical signal according to the intensity of these electrical signals from information about the type of gas and its concentration. Stable gas sensors have the ability to distinguish between gas, strong gas sensitivity, fast response signal detection, long life and other characteristics. Tungsten trioxide material has been widely studied because it is sensitive to NOx, NH3, H2S, H2 and other gases.

Experimental Procedure:

1. Firstly, exploring the electronic properties of doped titanium (Ti) surface WO3, establishing Ti-doped models, considering two cases of

alternative W6c Ti and W5c.

2.Secondly, studying the mechanism of Ti-WO3 sensitive surface with NO2, NH3 and H2. When Ti-WO3 surface was boiled with gas adsorption model, we take into account the four top adsorption sites: the bridge site oxygen O1c, flat bits oxygen O2c, Ti and 6 ligands tungsten W6c. NO2 and NH3 adsorption model. Bonded with N and oxygen O1c bridge of the best Ti- WO3 surface.

Conclusions:

1. The main reason for the change of resistance value is the electron transfer process by computing and analyzing of gas adsorption, density of states, and electron population in the gas adsorption, which reveals the mechanism of Ti-WO3 gas sensitive material.

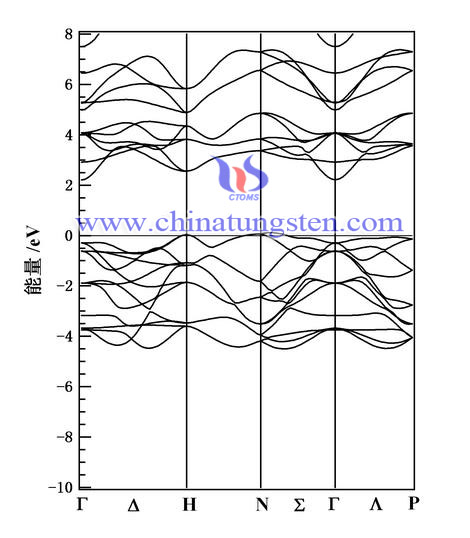

2. Contrasting separately NO2, NH3 and H2 with gas sensitive mechanism and Ti-WO3, WO3 undoped, we can find that the band gap of Ti-doped causes changes in the Fermi level, the number of electron-doped model in the adsorption process is much more, the magnitude of change in resistance of the adsorption Ti-WO3 material is increasing, which will help to improve the performance ratio of WO3-based gas sensors.

3. The results of surface Ti-doped W5c has the lowest surface energy and can form a stable doping structure by calculating, the energy band structure, density of states can be obtained from analysis. The change of band gap caused by Ti doping and new electronic band, which leds WO3surface performance to change.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |