Tungsten Copper Electrode Infiltration Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 November 2015 17:05

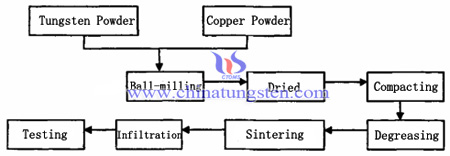

Tungsten copper electrode production process flow sheet as follow:

1. Preparation: Firstly, put tungsten powder, induced copper powder in ball grinding mill, and add 1% of stearate and dried and sieved to thereby obtain mixed powder after a while.

2. Compacting: Hydraulic machine pressing, we should concern the weighing in case of the loss of powder loss during the compacting process,

3. Degreasing: Using H2 as protective atmosphere when thermal degreasing, adhesive must be removed in order to avoid contamination and clean sintering furnace.

4. Sintering: Sintering in molybdenum wire furnace, H2 as protective atmosphere.

5. Infiltration: Using H2 as protective atmosphere and infiltrated copper at 1200-1300℃.

6.After-processing: The infiltrated tungsten copper alloy electrode after annealing treatment to improve the performance of the alloy, and then subjected to a surface treatment to remove excess copper.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com