Wear of Coated Tungsten Carbide Tool In Cutting H.S. Steel Ⅹ

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 November 2015 14:32

In last part we know that The flank wear progress of tungsten carbide tool with (Al,Cr)N coating changes little with cutting speed from 0.5 m/s to 1.0 m/s. And this part we explain further the similarity of tool wear mechanism between the cutting speed of 0.50 m/s and 1.00m/s.

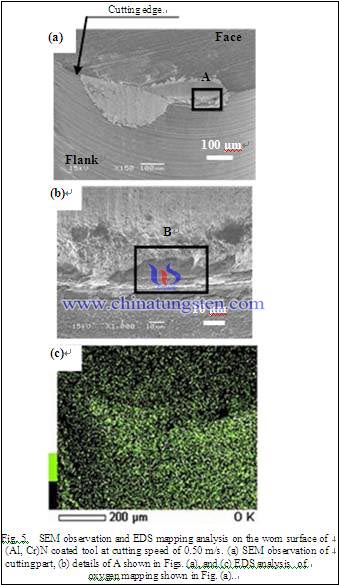

Fig. 5 shows the tool wear in the case of a cutting speed of 0.50 m/s. Fig. 5 (a) and (b) shows the SEM observation and Fig. 5 (c) shows the EDS analysis. Fig. 5 (b) shows the details of A shown in Fig. 5 (a). Fig. 5 (c) shows the EDS analysis in the case of the oxygen (O) mapping on the cutting part shownin Fig. 5 (a).

First, as compared with the wear of the tungsten carbide tool in the cutting speed 1.00 m/s shown in Fig. 1 (b) and that of the cutting speed 0.50 m/s shown in Fig. 5 (a), the tool wear of the cutting speed 0.50 m/s shows the same characteristics as that of the cutting speed 1.00 m/s. Next, as compared with the worn surface of the cutting speed 1.00 m/s indicated by “B” shown in Fig. 3 (ii)(a) and that of the cutting speed of 0.50 m/s indicated by “B” shown in Fig.5 (b), many striae scratched by any hard material are remarkably found on the worn surface in the case of both the cutting speed 1.00 m/s and the 0.50 m/s. Therefore, the main tool wear mechanism of the cutting speed 1.00 m/s and the 0.50 m/s is considered to be abrasive wear.

Finally, as compared with the oxygen element on the worn surface of the cutting speed 1.00 m/s shown in Fig. 3 (ii)(b) and that of the 0.50 m/s shown in Fig. 5 (c), the oxygen mapping on the cutting part shown in the cutting speed 0.50 m/s shows the same characteristics as that of the cutting speed 1.00 m/s. Therefore, the cutting speed is considered to have little influence on the cutting temperature within the range of the cutting speed from 0.50 m/s to 1.00 m/s.As mentioned above the cutting speed is considered to have little influence on the tool wear within the range of the cutting speed from 0.50 m/s to 1.00 m/s.

(To be continued. This article is divided into several parts. Here is part 10. For part 9 please refer to http://news.chinatungsten.com/en/tungsten-information/80632-ti-10439; for part 11, please refer to http://news.chinatungsten.com/en/tungsten-information/80698-ti-10452)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |