Geometric Characteristics of Tungsten Carbide Drill BitⅡ

- Details

- Category: Tungsten Information

- Published on Thursday, 19 November 2015 15:52

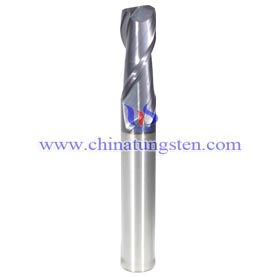

In last part we know that tungsten carbide drill bits are composed of tungsten carbide tips and shanks, either brazed or solid, used for cutting holes. This part will discuss the geometric characteristics of tungsten carbide drill bits.

Drill bit geometry has several characteristics:

1. The spiral (or rate of twist): the spiral in the tungsten carbide drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low spindle speeds, where removal of a large volume of swarf is required. Low spiral (low twist rate or "elongated flute") drill bits are used in cutting applications where high cutting speeds are traditionally used, and where the material has a tendency to gall on the bit or otherwise clog the hole, such as aluminum or copper.

2. The point angle, or the angle formed at the tip of the bit: it is determined by the material the bit will be operating in. Harder materials require a larger point angle, and softer materials require a sharper angle. The correct point angle for the hardness of the material controls wandering, chatter, hole shape, wear rate, and other characteristics.

(To be continued. This article is divided into several parts. Here is part 2. For part 1, please refer to http://news.chinatungsten.com/en/tungsten-information/80546-ti-10416; for part 3, please refer to http://news.chinatungsten.com/en/tungsten-information/80548-ti-10418)

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com