Tungsten Carbide Micro Drills and Micro Drilling Ⅵ

- Details

- Category: Tungsten Information

- Published on Thursday, 05 November 2015 16:39

In part 5 we know that the usage of fluid helps clear the chips and reduce drilling thrust force on the tungsten carbide drill and the chips affect in different ways for different hardness of materials. Here we explain the speeds and feeds of micro drilling process.

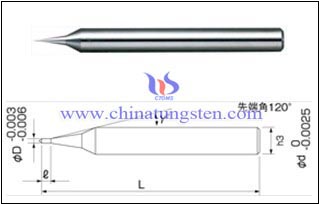

The recommended speeds and feeds for micro drilling are as varied as the materials which can be drilled. Micro drilling is not generally a high speed process since dwelling of the tungsten carbide micro drill at the bottom of the hole can cause hardening of the work piece leading to increased drilling forces. For most metals, typical spindle speeds are in the 2000 to 4000 rpm range and feeds are in the range of one micrometer per revolution, or so. Care must be taken when drilling plastics to avoid melting of the material which can lead to adhesion of the plastic to the tungsten carbide micro drill. This can cause drill breakage or poor sidewall smoothness.

(To be continued. This article is divided into several parts and this is part 6, for part 5 please refer to http://news.chinatungsten.com/en/tungsten-information/80076-ti-10280)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn