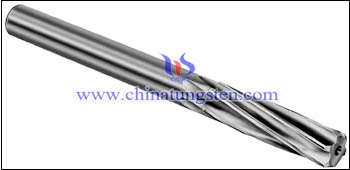

Tungsten Carbide Reamer Ⅻ

- Details

- Category: Tungsten Information

- Published on Monday, 26 October 2015 17:33

In part 11 we read that the accuracy and consistency of hole sizes made by a tungsten carbide reamer is affected by many variables in reaming process, such as reamer design and materials involved, and coolant fluid is recommended since it helps repeatedly maintain the hole size to be as close as possible to reamer diameter.And here we learn about the longevity of a tungsten carbide reamer and the equipments used for it .

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn