Cobalt Interlayed TiN-coated Tungsten Carbide Cutting Tool’s Performance Ⅲ

- Details

- Category: Tungsten Information

- Published on Friday, 11 September 2015 16:25

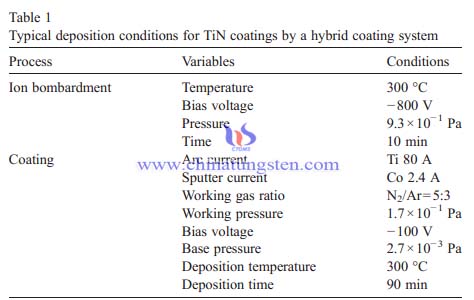

TiN coatings were deposited onto WC-Co substrate by a hybrid coating system, where an arc ion plating (AIP) method was combined with a magnetron sputtering technique. The schematic diagram of the apparatus was depicted in previous work . The WC-Co substrates with WC particle size of 0.7 μm and Co content of 10 wt. % were machined into disc types of 25 mm in diameter and 3 mm in thickness. The substrates were thoroughly cleaned in an ultrasonic bath cleaner using acetone and alcohol for 20 min. Prior to deposition, the substrates were cleaned again by ion bombardment using a bias voltage of − 800 V under Ar atmosphere for 10 min. Thin Co interlayer with various thicknesses were pre-deposited on the substrate by a d.c. magnetron sputtering technique using high purity (99.99%) Co targets. The interlayer thickness was controlled by sputtering time considering our back-data of thickness vs. sputtering time, where the thickness was measured with a stylus (α -STEP) and SEM. Right after pre-deposition of the interlayer, The TiN was coated with thickness o f ∼ 2.5 μm using an AIP technique. The typical deposition conditions are summarized in Table 1. The post annealing of samples was carried out at temperature range from 200 °C to 600 °C for 2 h in a vacuum chamber. The purity of used Ar and N2 gases was 99.999%.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn