Effect on Tungsten Polymer Injection Molding

- Details

- Category: Tungsten Information

- Published on Thursday, 30 July 2015 12:52

Tungsten polymer is a composition of various resins and tungsten powder which are mixed together through special metallurgical technology, which is injection molded. As its special high density of 11.34 g/cm3 min., tungsten polymer has a perfect radiation shielding performance comparable to lead for anti-radiation shielding.

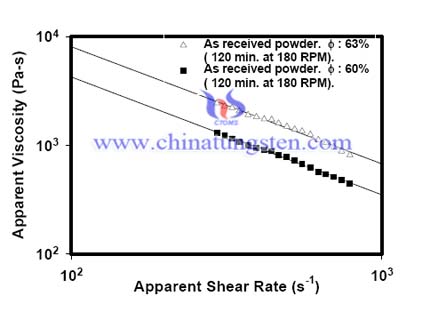

There has been conducted with as-received, agglomerated tungsten powder and rod milled tungsten powder to study the effect of mixing on the homogeneity of tungsten polymer injection molding. An increase in the mixing shear intensity increases the hydrodynamic force and contributes to the agglomerate size reduction. Deagglomeration during mixing improves the packing efficiency of the particles promotes homogeneity. Viscosity is a good indicator of the homogeneity of the feedstock. An increase in the homogeneity of the feedstock is reflected as a decrease in its viscosity. A perfectly homogeneous mixture will have the least viscosity. It is observed that with an increase in the intensity of mixing, the viscosity of the feedstock composed of as-received powder approaches that of the deagglomerated, rod milled powder.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn