Porous Silicon and Tungsten Oxide Thin Films Application

- Details

- Category: Tungsten Information

- Published on Monday, 30 March 2015 16:31

From the beginning of the industrial revolution, human society has made tremendous progress, while paying the environmental pollution and ecological deterioration of the enormous cost, from photochemical smog to acid rain, air pollution is getting worse, NO2 in which plays a very important addition to the impact .NO2 volcanic eruptions and other natural sources of foreign, mainly from the burning city car exhaust fuel. In addition, industrial production process can produce some NO2. It is estimated that, worldwide anthropogenic pollution emission of nitrogen oxides per year is approximately 53Mt. The main harm the atmosphere, water and soil, etc., can cause direct harm to the human respiratory system and eyes. Our indoor air quality standards in the ceiling on the NO2 concentration of about 0.12ppm.

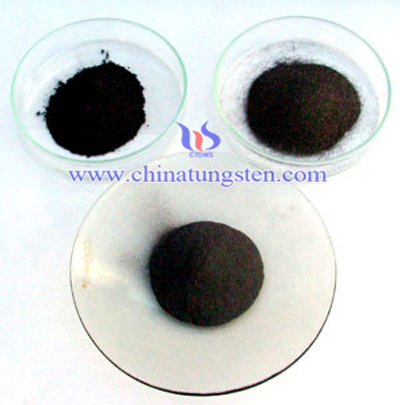

As people gradually improve the quality of life requirements, detection of NO2 gas in recent years has become an important topic, and then study the gas sensor has achieved rapid development, wherein the metal oxide semiconductor material meteoric rise, SnO2, ZnO, WO3, etc. are been extensively studied, but previous studies showed that the outstanding problems of these materials is that the higher operating temperature, selectivity and sensitivity, such as less than ideal, is not conducive to the development trend of integration and low power consumption, so people using the included material doped composite, low-dimensional technology, using different preparation methods, research and even low ambient temperature sensitive materials and other ways to reduce the operating temperature of the sensor.

Porous silicon because of its unique optical properties at room temperature and gas sensing properties of the application in the biomedical field, since the 1990s, are more and more attention. Porous silicon surface area because of its great and has a high surface activity, the external environment can absorb large amounts of gas molecules change their electrical properties or optical properties exhibited gas sensing performance. Application of porous silicon as a gas sensing material, generally use optical excitation, doped with another material or composite approach to achieve the purpose of improving the sensitivity or selectivity. Tungsten oxide as a common n-type metal oxide semiconductor material, also has good electrochromic properties and excellent gas sensing characteristics. In the n-type ordered porous silicon surface layer of tungsten oxide thin films by magnetron sputtering using porous silicon at room temperature and gas sensing performance of tungsten oxide NO2 better sensitivity advantages of gas sensing properties of composite structures. Aperture ordered porous silicon is between mesoporous silicon and macroporous silicon. Sufficiently large pore size and high porosity conducive to the formation of a good film with tungsten oxide composite interface, but also ensures high sensitivity to gases.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn