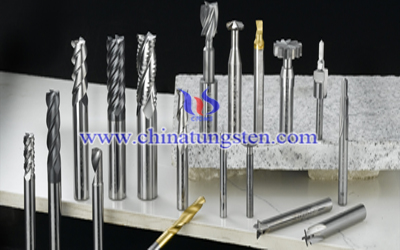

Tungsten Carbide Cutting Tools Oxidation Wear

- Details

- Category: Tungsten Information

- Published on Friday, 27 February 2015 09:08

A refractory metal tungsten carbide cutting tools hard metal compound and a binder made by powder metallurgy method, its hardness (HRA) is 89 to 94, much higher than the high-speed steel; at 540 ℃ hardness (HRA) 82 to 87, and the hardness of high-speed steel normal temperature (HRA83 ~ 86) fairly, but also has good chemical stability, heat resistance advantages. tools materials currently used for a lot of variety though, the new tools materials are also emerging, but still very popular tungsten carbide cutting tools material kind.

When cutting titanium, tungsten carbide cutting tools cutting when the temperature reaches 700 ~ 800 ℃, tungsten carbide materials WC, TiC, and Co compounds and plays the role of oxygen in the air, forming a lower hardness and strength oxide film. As air enters the cutting area is not easy, it is easy to form an oxide film on the flank position after tungsten carbide cutting tools. When cutting the workpiece surface by the oxide, chilled layer and hard impurity continuous friction points on the oxide film, resulting in oxidation of flank wear, also called boundary wear. When a large amount of wear and tear, will form oxidation wear grooves. After tungsten carbide cutting tools oxidation wear mainly as tools and vice flank flank have emerged oxidation wear phenomenon. And this phenomenon is more pronounced in high-speed cutting.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn