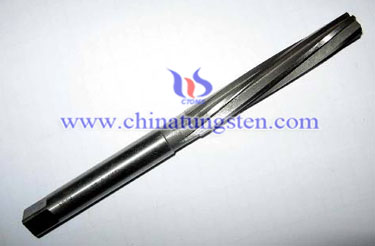

Tungsten Carbide Reamer Problems and Countermeasures (I)

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 October 2014 18:23

Tungsten carbide reamer may have some problems during reaming, which will be discussed below and their countermeasures will be given as well.

I. Pore diameter enlarging and errors

When this happens, some measures can be taken as follows: reducing the outer diameter of tungsten carbide reamers according to specific situation; adjusting the feeding amount or reducing machining allowance; reducing machine tool cutting edge angle; straightening or replacing reamers that can not be used anymore; finishing cutters by using oil stone; Keeping the run-out tolerance within the permitted range; selecting cutting fluid with good cooling performance; cleaning up the greasy dirt in reamer taper shanks and machine tool spindle bore-holes before installing reamers.

II. Pore diameter narrowing

When this happens, some measures can be taken as follows: Changing the outer diameter size of tungsten carbide reamers; increasing cutting speed; reducing feeding amount; increasing machine tool cutting edge angle; using oily cutting fluid with good lubricating performance; changing reamers regularly, and grinding the cutting edge of reamers correctly; considering the above mentioned factors when deciding reamer size or taking related values according to the actual situation.

III. Out-of-round internal holes after reaming

When the internal holes after reaming is out of round, measures can be taken as follows:

selecting qualified tungsten carbide reamer and controlling the hole position tolerance in the preparation process; adopting reamers with unequal pitch; adopting longer and more sophisticated guide sleeve; using qualified unprocessed work pieces; adjusting the machining tool cutting edge angle gap when reaming relatively more sophisticated holes using reamers with equal pitch; adopting proper clamping method and reducing clamping force.

IV. Prism on hole surface

When there is prism on hole surface, measures can be taken as follows: reducing reaming allowance; grinding the edge-line; using qualified unprocessed work pieces; adjusting machine tool cutting edge angle.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn