What Are the Uses of Tungsten Resin?

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 September 2025 17:24

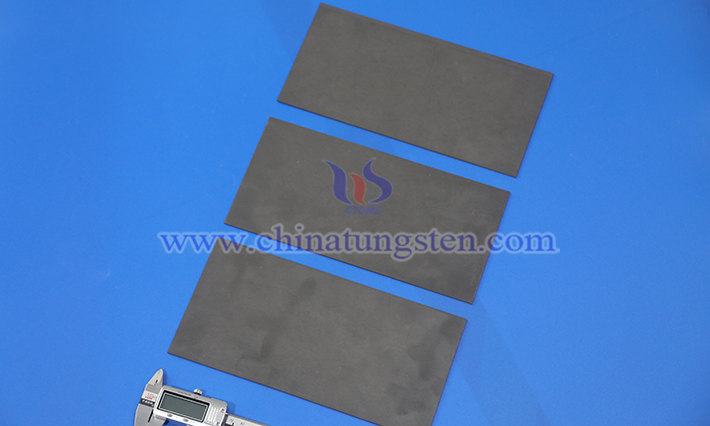

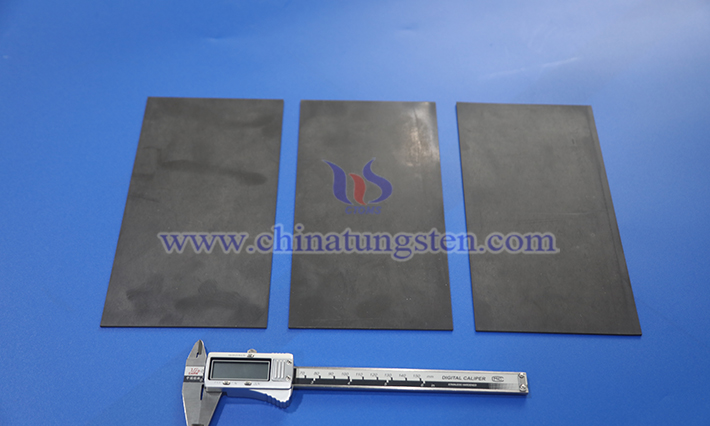

Tungsten resin, leveraging its high density, non-toxicity, radiation shielding capability, and processing flexibility, finds wide-ranging uses in medical, defense, industrial, civilian, and emerging technology fields.

1. Radiation Protection in Medical Fields

Tungsten resin’s high density and excellent radiation shielding performance make it widely used in medical equipment. It effectively absorbs X-rays and gamma rays, offering higher shielding efficiency than lead while being non-toxic, aligning with green environmental requirements. Common applications include: CT scanners and X-ray machines—used to manufacture shields and protective panels, reducing radiation exposure for patients and medical staff; nuclear medicine—employed as a shielding layer for radioactive isotope containers, ensuring safe transport and storage; and radiotherapy—used in protective screens and guiding devices made from tungsten resin to direct radiation beams, protecting healthy tissues.

2. Counterweights and Protection in Defense and Aerospace

Tungsten resin’s high density and impact resistance make it highly favored in defense and aerospace applications. Key uses include: missile and satellite counterweights—tungsten resin is used in balance blocks to ensure missile flight stability and satellite attitude control; military armor—incorporated into armor plates for vehicles and tanks, providing impact resistance to enhance survivability; and aerospace components—utilized in aircraft and helicopter counterweights to optimize center-of-gravity distribution, improving flight stability. Its processing flexibility allows for rapid molding into complex structures, meeting the precision demands of defense applications.

3. Vibration Control and Wear-Resistant Components in Industrial Fields

In industrial manufacturing, tungsten resin’s density and wear resistance make it suitable for various scenarios: vibration dampers—used as counterweights in car engines, wind turbines, and industrial machinery to reduce vibration and noise; wear-resistant coatings—tungsten’s high hardness enables tungsten resin to serve as a wear layer for mechanical parts like gears and bearings, extending service life; and precision instruments—applied in optical equipment and lasers to stabilize structures, preventing accuracy loss due to vibration.

4. Eco-Friendly Alternatives in Civilian Fields

Tungsten resin’s non-toxicity positions it as a green alternative to traditional lead materials, with widespread civilian applications: fishing tackle manufacturing—tungsten resin fishing weights replace lead weights, preventing water pollution and protecting aquatic ecosystems; sports equipment—used in golf club counterweights to optimize swing balance or in archery gear to enhance arrow stability; and consumer electronics—employed in mobile phones and laptops as antenna shields or vibration motor counterweights, improving signal stability and user experience.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com