What Are the Characteristics of Tungsten Resin?

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 September 2025 17:22

Tungsten resin is a composite material made by mixing high-purity tungsten powder with polymer resins (such as epoxy, polyurethane, or polyethylene). It is widely used in defense, medical, industrial, and environmental fields, thanks to its unique physical, chemical, and processing characteristics.

1. High Density and Adjustability

The most notable characteristic of tungsten resin is its high density, typically ranging from 8.0 g/cm³ to 11.0 g/cm³, close to lead but with a more compact volume, making it suitable for space-constrained applications. Compared to pure tungsten metal (19.3 g/cm³), its density can be flexibly adjusted by varying the tungsten powder content (usually 70%–90%) to meet different needs.

2. Excellent Radiation Shielding Performance

Tungsten resin excels in radiation protection due to tungsten’s high atomic number, offering strong absorption of X-rays and gamma rays. Unlike lead, it is non-toxic, aligning with current environmental demands, and is an ideal choice for medical equipment (e.g., CT machine collimators, X-ray shields) and the nuclear industry (e.g., reactor linings, radioactive material transport containers).

3. Good Mechanical Properties

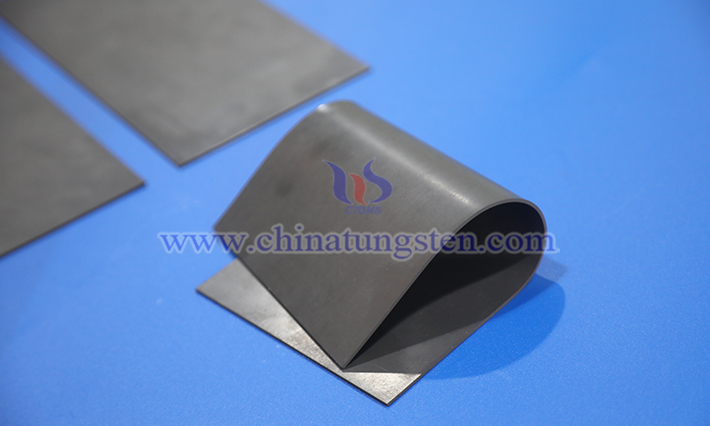

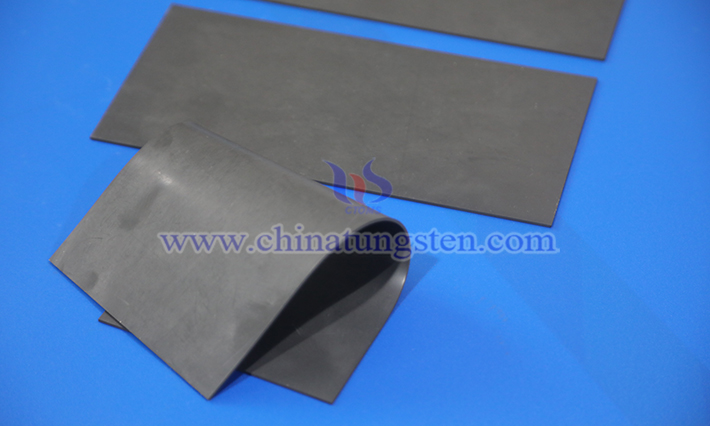

Tungsten resin combines tungsten’s hardness with the toughness of resin, exhibiting balanced mechanical properties. Its tensile strength typically ranges from 50–80 MPa, with an elongation at break of 5%–10%, surpassing pure resin materials. With a Mohs hardness of 7.5, it offers excellent wear resistance, suitable for high-friction environments like wear-resistant coatings for mechanical parts or military vehicle armor plates. Additionally, its good impact resistance allows it to withstand moderate mechanical stress, making it ideal for dynamic load scenarios. Compared to metallic tungsten, tungsten resin’s flexibility enables easier processing into complex shapes, reducing manufacturing difficulty.

4. Excellent Chemical and Thermal Stability

Tungsten resin demonstrates strong chemical stability, resisting acid and alkali corrosion, as well as water and moisture, making it suitable for humid or chemically corrosive environments. Its thermal stability allows normal use across a wide temperature range, withstanding higher temperatures in the short term, suitable for various climate conditions and industrial scenarios.

5. Environmental Friendliness and Safety

The non-toxicity of tungsten resin is a key advantage over lead. Traditional lead materials may release harmful substances during production and use, whereas tungsten resin meets environmental standards and is widely used in safety-critical fields such as medical devices, fishing tackle, and children’s toys. Additionally, its waste can be recycled through pyrolysis or mechanical separation, reducing resource waste and environmental pollution.

6. Processing Flexibility and Cost Advantage

Tungsten resin offers superior processing performance compared to pure tungsten or tungsten alloys. With a lower molding temperature, it can be formed into complex geometric shapes through injection molding, casting, or extrusion, boasting high production efficiency and lower costs than tungsten metal.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com