Uses of Tungsten Wires in Airport Runway Marker Lights

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 15:43

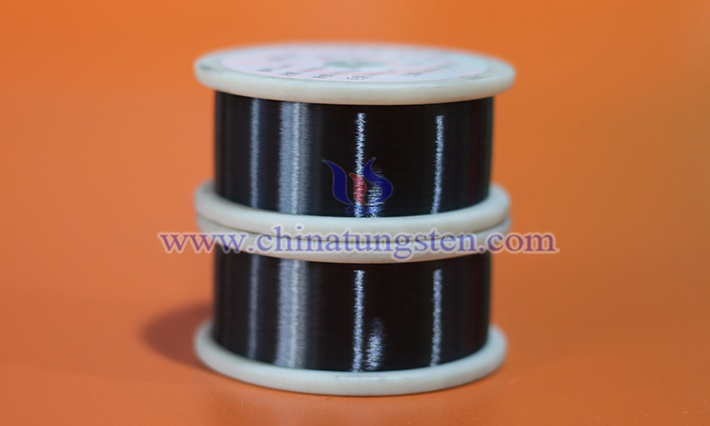

Tungsten wires, with their high melting point, high temperature resistance, and corrosion resistance, once played a key role in airport runway marker lights. They were particularly popular during the era of halogen tungsten lamps, where they were widely used for centerline and touchdown zone lights. While LEDs have gradually replaced traditional light sources with technological advancements, the physical advantages of tungsten wires still make them valuable in specific applications, and their historical contributions cannot be ignored.

I. Physical Properties and Lighting Advantages of Tungsten wires

1. High Melting Point and High-Temperature Resistance

Tungsten has a melting point of 3410°C, one of the highest among metals. This property enables it to operate stably in high-temperature environments, preventing it from melting or deforming due to temperature increases, making it a perfect match for halogen tungsten lamps, which operate based on the incandescent principle. Airport runway marker lights require long-term, high-brightness operation, and tungsten wires' high-temperature resistance ensures the reliability of the light source. 2. Corrosion and Oxidation Resistance

Tungsten wires form a protective oxide layer at high temperatures, effectively resisting corrosion in outdoor environments. This adapts to the large temperature swings and frequent humidity fluctuations found at airports, reducing maintenance frequency.

3. Low Thermal Expansion Coefficient

Tungsten wires have a low thermal expansion coefficient, maintaining dimensional stability during temperature fluctuations. This prevents structural deformation of the lamp due to thermal stress, ensuring the lamp's precision.

4. High Strength and Hardness

Tungsten wires are vibration- and wear-resistant, making them suitable for the vibrations experienced during aircraft takeoff and landing, extending lamp life. This performance is particularly prominent in critical locations such as runway centerline lights.

II. Specific Applications of Tungsten wire in Airport Marker Lights

1. Runway Centerline Lights

White tungsten halogen lamps are arranged at intervals of 15 or 30 meters to mark the centerline from the runway threshold to the runway end. Certain areas (e.g., 900 to 300 meters from the runway end) are illuminated red to alert pilots during landing. 2. Touchdown Zone Lights

Short horizontal bars of white tungsten-halogen lamps are arranged symmetrically on either side of the runway centerline, spaced 30 or 60 meters apart. They indicate the landing zone and ensure safe touchdown.

3. Runway Threshold and End Lights

The green threshold and red end lights, both using tungsten-halogen lamps, clearly mark the runway boundaries, helping pilots accurately determine their position in low visibility conditions.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com