Tungsten Wire as Electron Tube Hot Cathode

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 18:53

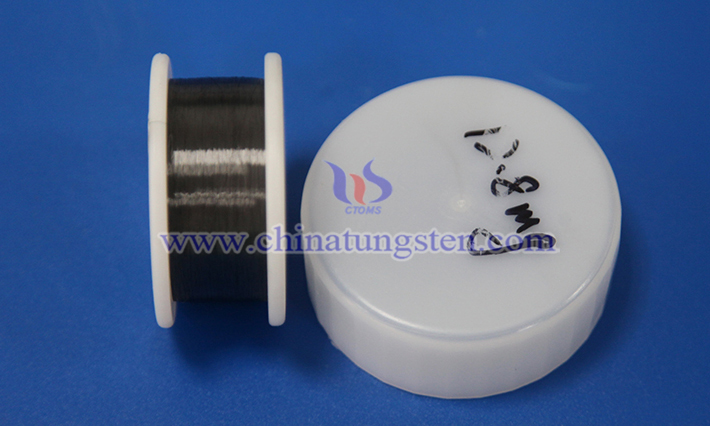

Tungsten wire, due to its high melting point, low vapor pressure, high thermal stability, and controllable electron emission properties, is an ideal material for electron tube hot cathodes.

I. Working Principle of Hot Cathode

Electron tubes (vacuum tubes) achieve signal amplification or rectification by emitting electrons from hot cathodes. The basic process is as follows:

1. Thermionic Emission: The cathode material is heated to a high temperature (typically above 1000°C), allowing surface electrons to gain sufficient energy to overcome the work function, forming an electron stream.

2. Vacuum Environment: The high vacuum within the tube (pressure below 10⁻⁴ Pa) prevents collisions between electrons and gas molecules, ensuring free electron movement.

3. Electric Field Acceleration: A positive voltage is applied to the anode, attracting electrons to form a current, achieving signal amplification or rectification.

II. Advantages of Tungsten Wire as a Hot Cathode

1. High Melting Point and Thermal Stability

Tungsten has a melting point of 3422°C, the highest of all metals, and can withstand high temperatures without melting.

At electron tube operating temperatures (approximately 1000-2000°C), tungsten wires maintain structural stability, preventing deformation or fracture due to thermal expansion or softening.

2. Low Vapor Pressure

At high temperatures, tungsten has an extremely low vapor pressure (much lower than other metals such as copper and iron), significantly reducing cathode material evaporation and extending electron tube life.

Low vapor pressure also makes it easier to maintain vacuum within the tube, reducing collisions between electrons and gas molecules and improving emission efficiency.

3. High Work Function and Controlled Emission

Pure tungsten has a high work function (approximately 4.5 eV), requiring relatively high temperatures to emit electrons. However, through doping (such as with thorium or cerium) or coating with oxides (such as barium or strontium oxides), the work function can be reduced to below 2 eV, enabling low-temperature, efficient emission. Thoriated tungsten wire: Thorium atoms adsorbed on the surface form a low work function layer, improving emission efficiency while maintaining the tungsten matrix's high melting point.

Oxide cathode: Barium strontium calcium oxide is coated on the tungsten wire surface, resulting in higher emission efficiency but a shorter lifespan, making it suitable for low-power applications.

4. Mechanical Strength and Corrosion Resistance

Tungsten wire offers high strength and hardness and can be processed into thin wires, improving heating efficiency.

Its chemical properties are stable and it is not easily reacted with residual gases at high temperatures, preventing cathode poisoning (such as oxidation or sulfidation).

III. Typical Applications of Tungsten Hot Cathodes

1. Power Electron Tubes

High-power transmitting tubes: Such as the tetrodes and pentodes used in broadcast transmitters. Tungsten cathodes can withstand high current densities (over 10 A/cm²) and achieve kilowatt-level power output.

Traveling Wave Tubes: Used in satellite communications and radar systems, tungsten cathodes provide a stable electron beam, supporting high-frequency (GHz-level) signal amplification.

2. X-ray Tube

A tungsten wire acts as a cathode. When heated, it emits electrons that strike a metal target (such as tungsten or molybdenum), producing X-rays. Its high melting point ensures the cathode is not damaged by high currents.

3. Vacuum Fluorescent Display (VFD)

When heated, the tungsten wire cathode emits electrons, stimulating the phosphor to emit light. This was used in early calculators and instrument displays.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com