Effect of Material Purity of Tungsten Crucible on Properties

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:27

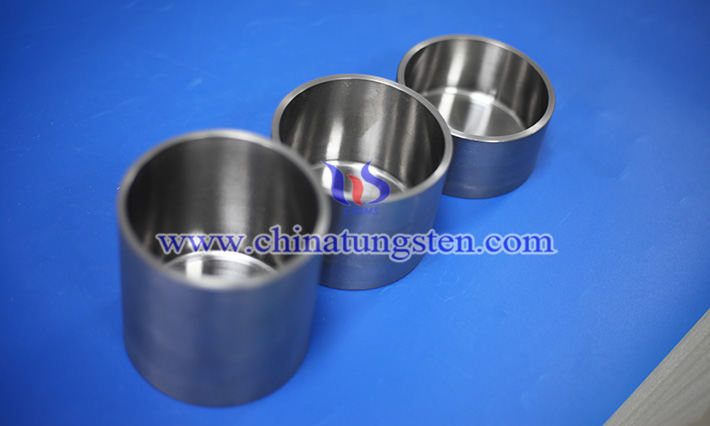

As an indispensable key material in the high-temperature industry, the performance of tungsten crucible directly affects the production efficiency and product quality in many fields such as crystal growth, metal melting and vacuum evaporation. Among the many performance indicators, the purity level of tungsten material not only determines the physical properties of the crucible, but also has a profound impact on its chemical stability, mechanical strength and service life.

First of all, the material purity of tungsten is directly related to the mechanical characteristics of the crucible. High-purity tungsten usually contains very few impurities, especially the strict control of oxygen, nitrogen, carbon and other elements, so that the internal lattice defects of the material are reduced, and the grains are more uniform and dense. In this way, the tensile strength, fracture toughness and thermal fatigue characteristics of the crucible are significantly improved. Under the condition of high temperature and repeated cycles, high-purity crucibles can effectively resist crack propagation caused by thermal stress, thereby prolonging their service life. On the contrary, the impurities in low-purity tungsten often become stress concentration points, which can easily cause microcracks and embrittlement of materials, resulting in early failure of the crucible in high-temperature environments.

Secondly, purity has a great influence on the chemical stability of the crucible. Impurity elements such as oxygen and nitrogen may react with tungsten in a high-temperature environment to form oxides or nitrides, forming a local brittle phase. The presence of these impurity phases not only destroys the dense structure of the crucible, but also reduces its resistance to corrosion of molten metal or chemical atmospheres. Especially in high-temperature oxidation or reduction atmospheres, crucibles with high purity show stronger oxidation and corrosion resistance, reducing the consumption of crucible materials and the risk of contamination, thereby ensuring the purity and safety of the process.

In addition, purity has a significant effect on the thermophysical characteristics of the crucible. High-purity tungsten typically has a higher thermal conductivity and a more stable coefficient of thermal expansion, which helps to improve the heat conduction efficiency and uniform distribution of thermal stress in the crucible at high temperatures. Good thermal conductivity can reduce local overheating and temperature differences, and reduce the probability of material fatigue and cracking caused by thermal stress. At the same time, the stable thermal expansion performance enables the crucible to maintain dimensional stability during thermal cycling, avoiding deformation and damage caused by thermal expansion mismatch.

In addition, the material purity of tungsten crucible also directly affects its processing properties. High-purity tungsten powder makes it easier to achieve a uniform and dense sintering structure, reduces porosity and microcracks, and provides a better material basis for subsequent machining. The dimensional accuracy and surface quality of the machined tungsten crucible are easier to meet the design requirements, which is essential to ensure tightness and thermal field uniformity in high-temperature processes.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com