Potential Applications of Tungsten Crucibles in the Nuclear Industry

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:11

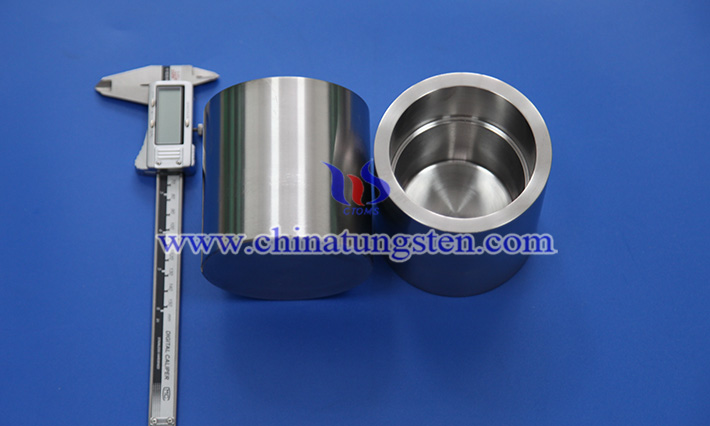

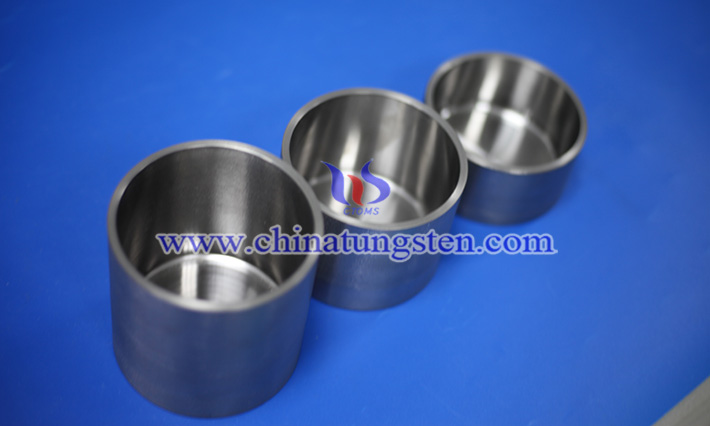

Among many components, tungsten crucibles are attracting more and more attention from research institutions and industries due to their excellent heat resistance, corrosion resistance, radiation resistance and other characteristics, and its potential applications in nuclear fuel processing, high-level radioactive waste treatment and next-generation nuclear energy systems are worthy of in-depth discussion.

First of all, in the high-temperature smelting and remanufacturing of nuclear fuel, W crucibles show obvious advantages. Thorium-based or uranium-based nuclear fuels often need to be operated at high temperatures of more than 2000°C during synthesis, melting and reprocessing, and ordinary metal or ceramic crucibles are prone to reaction or structural instability. In contrast, tungsten's high melting point (3410°C) and excellent thermal stability enable it to operate stably in high-temperature vacuum or inert atmosphere environments for a long time, while avoiding harmful chemical reactions with fuel components, helping to improve fuel purity and recasting efficiency.

Secondly, the application of tungsten crucible in the melting and sealing treatment of nuclear waste also has a good prospect. In some radioactive waste curing processes, a highly active waste liquid or powder is heated, melted, and encapsulated into a glass or ceramic body. Because these substances contain reactive elements such as oxygen, fluorine, and sulfur, they are prone to corrode container materials during the melting process. Tungsten, on the other hand, exhibits strong corrosion resistance under proper atmospheric protection, and its low activity intrinsic properties reduce the risk of cross-contamination between radionuclides and crucible materials. As a result, W crucibles can be used as candidates for high-performance containers for melting high-level radioactive waste.

In addition, tungsten crucibles are expected to play an important role in advanced reactor systems in the future. The next-generation nuclear energy system, represented by new reactors such as molten salt reactors and gas-cooled fast reactors, generally has a working temperature of up to 700°C or even higher, which puts forward more stringent requirements for the thermal stability and corrosion resistance of structural materials. If these reactors involve high-temperature operation of liquid metals or molten salts, W crucibles can be used in critical steps such as material compatibility experiments, molten salt analysis, or radioisotope synthesis to support the sustainable development of nuclear technology.

Of course, the wide application of tungsten crucibles in the nuclear industry still faces some challenges, such as high material cost, difficult processing, and easy corrosion in strong oxidizing atmosphere. To overcome these obstacles, researchers are trying to develop tungsten alloy materials, surface coating technologies, and composite structural crucibles to improve their overall performance and reduce manufacturing and maintenance costs.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com