Selection of Tungsten Wire in Glass Heating System

- Details

- Category: Tungsten Information

- Published on Thursday, 26 June 2025 19:23

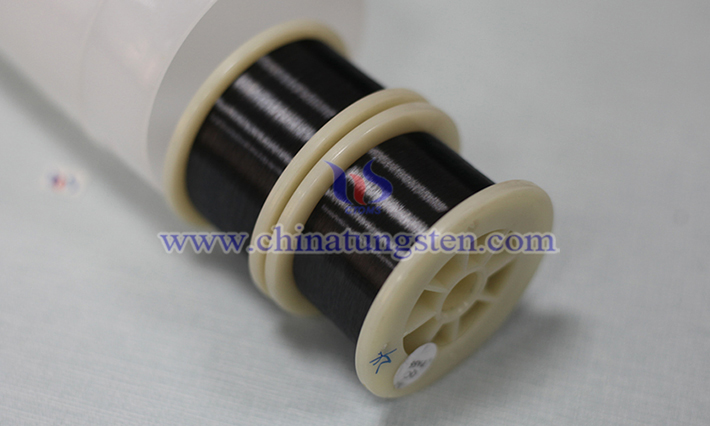

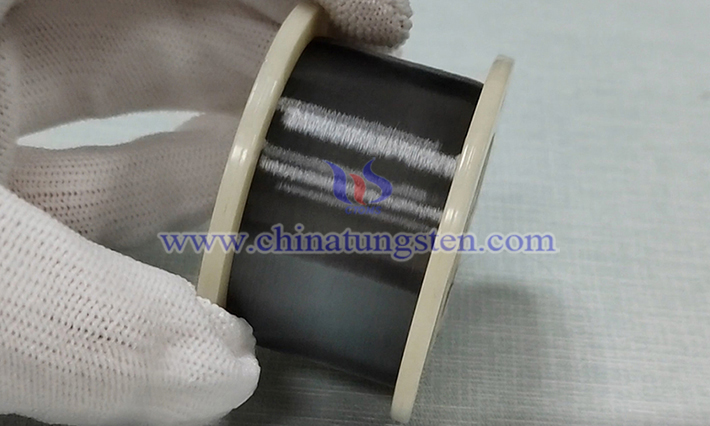

Tungsten wire has an extremely high melting point (about 3422℃) and is an ideal high temperature resistant material in glass heating system. Its resistivity is moderate, it can heat up quickly when heated, and it has good thermal stability and is not easy to deform or melt. Tungsten wire also has a low thermal expansion coefficient and can maintain structural stability at high temperatures. In addition, the chemical inertness of tungsten makes it difficult to react with glass or surrounding gases at high temperatures, extending its service life.

I. Selection of Tungsten Wire in Glass Heating System

1. Diameter and Resistance: The diameter of tungsten wire directly affects the resistance and heating power. Thin tungsten wire has a higher resistance and is suitable for rapid heating but is easy to break; thick tungsten wire has a lower resistance and is suitable for stable heating but heats up slowly. The appropriate diameter needs to be selected according to the power demand and heating rate of the glass heating system.

2. Purity: High-purity tungsten wire (more than 99.95%) can reduce the volatilization of impurities, avoid contaminating glass or reducing the life of the wire. In special applications, doped tungsten wire (such as potassium, aluminum, etc.) can be selected to improve creep resistance.

3. Surface Treatment: The smooth surface of tungsten wire can reduce oxidation and cracking and extend life. In some scenarios, surface coating (such as anti-oxidation coating) can further improve durability.

4. Working Environment: Glass heating systems often involve high temperatures and specific atmospheres (such as vacuum or inert gas). Tungsten wire needs to remain stable in the working environment to avoid oxidation or embrittlement. If in an oxygen-containing environment, additional protection measures are required, such as sealing or inert gas protection.

5. Mechanical Properties: Tungsten wire is easy to become brittle at high temperatures. When selecting, its ductility and tensile strength should be considered to ensure that it is not easy to break during processing and installation.

II. Precautions for Using Tungsten Wire in Glass Heating

In glass heating systems, tungsten wire is usually used for processes such as melting, annealing or molding. During design, it is necessary to ensure that the tungsten wire distributes heat evenly to avoid local overheating that causes uneven stress on the glass. During installation, the tungsten wire should be firmly fixed to prevent breakage caused by vibration or thermal expansion. In addition, the aging of the tungsten wire, such as surface oxidation or resistance change, needs to be checked regularly and replaced in time to ensure system stability.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com