Applications of High-Density Tungsten Alloy Counterweight Blocks

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 June 2025 11:07

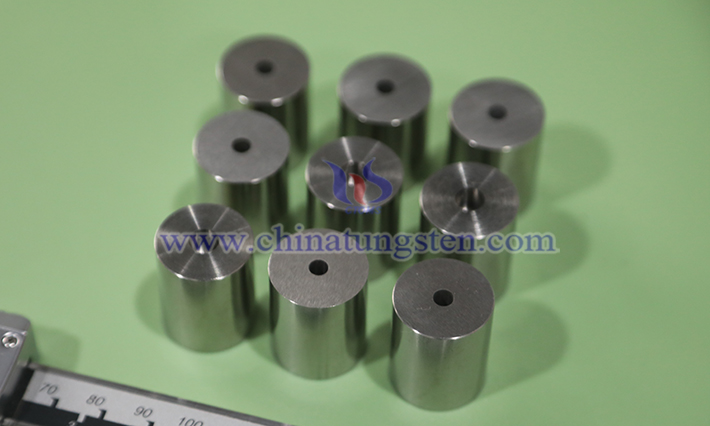

High-density tungsten alloy counterweight blocks, with densities typically ranging from 16.5 to 19.0 g/cm³, along with excellent mechanical properties and stability, play a critical role in adjusting center of gravity and balancing loads across various fields.

I. Aerospace

Engine Counterweights: Used in aircraft turbine engines to balance high-speed rotating impellers, reducing vibration and noise, and preventing mechanical failures due to center-of-gravity shifts.

Satellite Attitude Control: Adjusts the center of mass in orbiting spacecraft, working with propulsion systems for precise orbit changes or attitude stabilization, such as in the counterweights of Beidou satellite solar panel supports.

Helicopter Rotor Counterweights: Mitigates centrifugal force imbalances during rotor rotation, enhancing flight stability and reducing airframe fatigue.

II. Marine Engineering and Shipbuilding

Large Cargo Ship Ballast Counterweights: Installed at the bottom of ship hulls when empty to increase draft depth, preventing tilting due to uneven buoyancy.

Deep-Sea Explorer Counterweights: Provides sinking power for underwater robots or submersibles, with adjustable distribution controlling depth and posture.

Offshore Drilling Platform Stabilization: Mounted on the legs or deck bases of offshore platforms to resist wave impacts and wind loads, preventing overturning risks.

III. Industrial Machinery and Equipment

Crane Jib Counterweights: Installed at the end of tower crane balance arms to create a moment balance with the jib load, preventing tipping due to overloading.

Punch Press and Forging Machine Counterweights: Counteracts inertial forces from high-speed slider movements, reducing vibration and improving machining precision.

High-Speed Centrifuge Counterweights: Adjusts the dynamic balance of centrifuge drums, preventing severe vibrations from high-speed rotation that could damage equipment.

IV. Medical and Nuclear Industries

Radiotherapy Equipment Counterweights: Used in linear accelerator treatment heads to balance the radiation head’s center of gravity, ensuring accurate beam targeting.

Nuclear Reactor Pressure Vessel Counterweights: Serves as fixed weights for pressure vessels while leveraging tungsten alloy’s radiation shielding properties to block neutron radiation.

V. Sports and High-End Consumer Goods

Golf Club Counterweights: Embedded in clubhead bases to adjust the sweet spot, enhancing energy transfer during swings for greater distance and accuracy.

Mechanical Watch Counterweights: Micro-tungsten alloy weights in balance wheels adjust oscillation frequency, improving timekeeping precision.

VI. Other Special Scenarios

Seismograph Pendulum Counterweights: Increases pendulum mass in seismometers, enhancing sensitivity and stability in detecting seismic waves.

Racing Car Counterweights: Installed at specific chassis or body points to adjust front-rear axle load distribution (e.g., F1 chassis weights), optimizing handling; luxury car engine bay counterweights reduce vibration and noise.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com