Preparation Cost Factors of Barium Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 04 June 2025 17:14

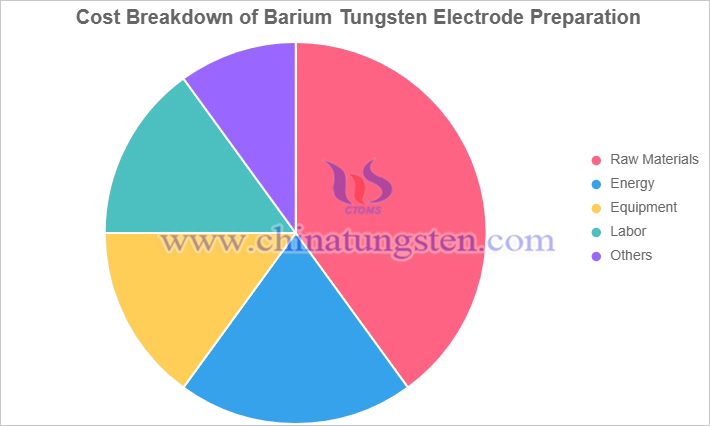

Barium tungsten electrode is an important cathode material, widely used in vacuum electronic devices such as microwave tubes, X-ray tubes, etc. Its preparation cost factors include raw materials, energy, equipment, labor, production efficiency and scrap rate.

1. Raw Material Cost

Tungsten powder and barium compounds are the core raw materials for preparing barium tungsten electrodes. As a rare metal, tungsten has a high price and obvious fluctuations, and the quality and price of barium compounds will also have a direct impact on the cost.

2. Energy Consumption

Sintering is a key step in the preparation process, which requires a high temperature environment and high energy consumption. Energy prices and the energy efficiency of the sintering process directly determine this part of the cost.

3. Equipment Investment and Maintenance

Equipment such as pressing and sintering are indispensable tools to produce barium tungsten electrodes, and their purchase costs, maintenance costs and depreciation costs account for a certain proportion of the total cost.

4. Labor Cost

The preparation process requires skilled workers to operate and monitor, and the level of labor wages and labor intensity will affect the cost, especially in the links with higher technical requirements.

5. Production Efficiency

The level of production efficiency determines the cost of a unit product. An efficient production process can dilute fixed costs and thus reduce unit costs.

6. Scrap Rate

The scrap rate in the preparation process directly affects the utilization rate of raw materials and energy. The higher the scrap rate, the greater the waste, and the higher the cost.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com