Molybdenum Bar

- Details

- Category: Tungsten Information

- Published on Wednesday, 04 June 2025 15:11

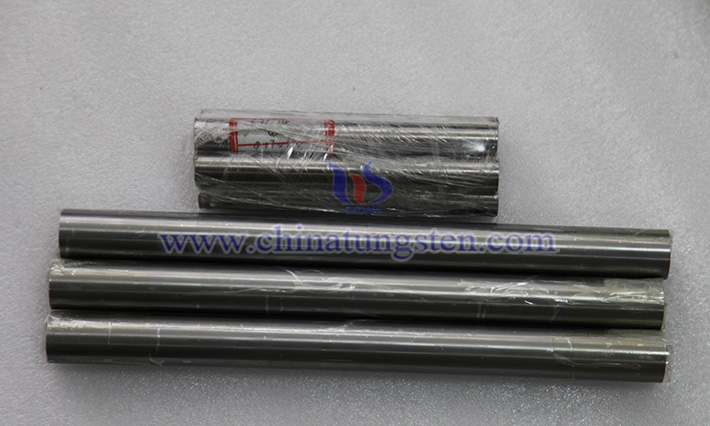

As a typical product made from the refractory metal molybdenum (Mo), molybdenum bar is a rod - shaped item with molybdenum as its primary raw material. Therefore, it is often referred to as a molybdenum rod or molybdenum stick. In English, it is known as "molybdenum bar" or "molybdenum rod." With a purity of up to 99.7%, it is widely used in metallurgy, power equipment, and other fields due to its excellent thermal, mechanical, chemical, and electrical properties.

From the perspective of physical and chemical characteristics, the standard molybdenum bar inherits all the advantages of metallic molybdenum. These include a bright metallic luster on the surface, high melting point, high density, high strength, high hardness, low thermal expansion coefficient, excellent high - temperature resistance, as well as good electrical and thermal conductivity. It is worth noting that the natural color of the molybdenum bar is silvery. However, when the surface retains lubricants or oxide coatings, the bar appears black.

Regarding the production process, the manufacturing flow of the molybdenum bar is as follows: molybdenite concentrate → oxidation roasting → roasted sand → leaching → ammonium molybdate solution → purification → neutralization and crystallization → ammonium polymolybdate → dissolution → ammonium molybdate solution → evaporation crystallization → ammonium dimolybdate → calcination → molybdenum trioxide → reduction → molybdenum powder → forming and sintering → molybdenum bar. Note that ammonia water is added during leaching and dissolution, hydrochloric acid is added during neutralization and crystallization, and hydrogen gas is used during the reduction stage.

In terms of shape and appearance, the molybdenum bar comes in both rectangular and cylindrical forms. Based on surface condition, it can be categorized as alkali - cleaned, ground, turned, and polished. Based on application, it can be pided into standard molybdenum bar, high - temperature molybdenum bar, and steelmaking - grade molybdenum bar.

The alkali - cleaned molybdenum bar is processed by immersing an ordinary molybdenum rod in an alkaline solution to remove surface impurities. This bar has a smooth surface and a gray metallic luster. The alkaline solution is typically a mixture of sodium hydroxide and either sodium carbonate or trisodium phosphate. The ground molybdenum bar undergoes rough grinding, intermediate grinding, and fine grinding, resulting in a smooth surface with silvery - gray metallic luster and minimal dimensional deviation. The turned molybdenum bar is machined using a lathe. Although its surface is flat and metallic, it is rougher compared to alkali - cleaned or ground bars. The polished molybdenum bar is processed using mechanical, chemical, or electrochemical polishing methods to reduce surface roughness, resulting in a bright and smooth finish.

The standard molybdenum bar is mainly used for producing molybdenum wire. The high - temperature molybdenum bar is used in the manufacture of high - strength wire for wire - cutting, high - temperature heating elements, electric light source materials, vacuum electronic devices, and high - temperature structural components. The steelmaking - grade molybdenum bar is primarily used as an additive in steel production to improve the high - temperature strength and toughness of the steel.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com