The Role of Cut-Resistant Tungsten Wire Protective Gloves

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 April 2025 19:28

The role of cut-resistant tungsten wire protective gloves is primarily reflected in their exceptional protective performance and wide range of application scenarios, as detailed below:

1. Outstanding Cut Resistance

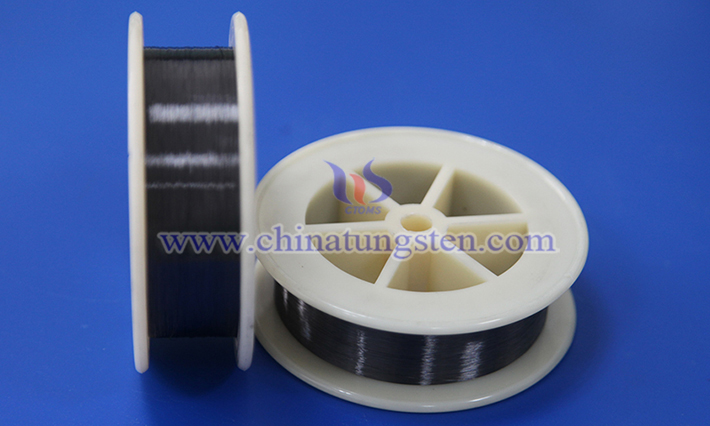

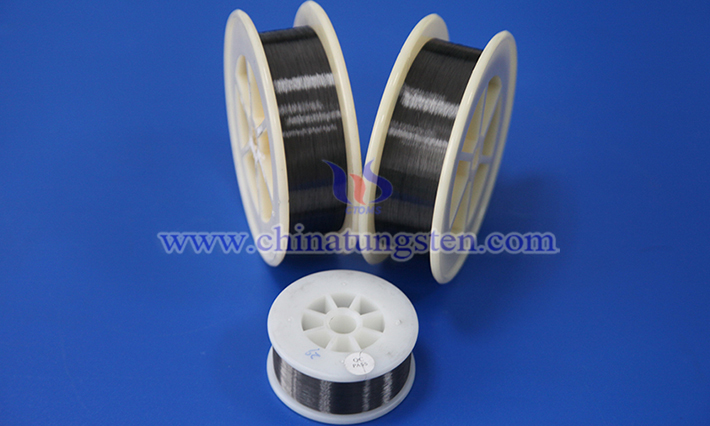

Tungsten wire, as a high-strength metal material, boasts excellent cut-resistant and abrasion-resistant properties. Compared to traditional materials like stainless steel or Kevlar, tungsten wire gloves can withstand greater cutting forces, effectively protecting against sharp objects such as knives, glass shards, and metal edges, providing reliable hand protection.

2. Lightweight and Flexible Design

Thanks to the high strength of tungsten wire, these protective gloves can be designed to be thinner and more form-fitting. Compared to traditional bulky gloves, tungsten wire gloves maintain a high level of protection while enhancing comfort and flexibility, making them suitable for prolonged use and reducing hand fatigue.

3. High-Temperature and Corrosion Resistance

Tungsten wire’s ability to withstand high temperatures and resist corrosion ensures that the gloves remain stable in hot, humid, or corrosive environments. This makes them ideal for industries such as metal processing, glass manufacturing, and chemical production, meeting the protective needs of complex working conditions.

4. Wide Range of Applications

Industrial Manufacturing: In high-risk tasks like metal cutting, stamping, and welding, tungsten wire gloves effectively prevent cuts and burns to the hands.

Glass Processing: When handling glass products, the gloves protect against cuts from glass fragments, ensuring worker safety.

Firefighting and Rescue: During rescue operations, the gloves shield against sharp objects while offering high-temperature resistance, adapting to challenging environments.

Military and Security: As part of stab-resistant gear, tungsten wire gloves can defend against attacks from knives and other sharp weapons, enhancing personnel protection.

5. Improved Efficiency and Safety

The protective properties of tungsten wire gloves significantly reduce the risk of hand injuries, minimizing downtime due to workplace accidents and boosting productivity. Additionally, their lightweight design enhances operational flexibility, contributing to greater precision and safety during tasks.

6. Compliance with Industry Standards

Cut-resistant tungsten wire protective gloves typically meet international or industry safety standards (e.g., EN 388), with clearly defined protection levels suited to various risk environments.

7. Durability and Cost-Effectiveness

The high strength and wear resistance of tungsten wire extend the gloves’ lifespan, reducing replacement frequency and lowering protective equipment costs for businesses.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com