Characteristics of cut-Resistant Tungsten Wire Protective Gloves

- Details

- Category: Tungsten Information

- Published on Tuesday, 08 April 2025 19:09

Cut-resistant tungsten wire protective gloves are a specially designed hand safety protection equipment, usually used in scenarios that require high-intensity cut resistance, such as industrial operations, metal processing or glass processing. Its main characteristics include:

1. High Cut Resistance

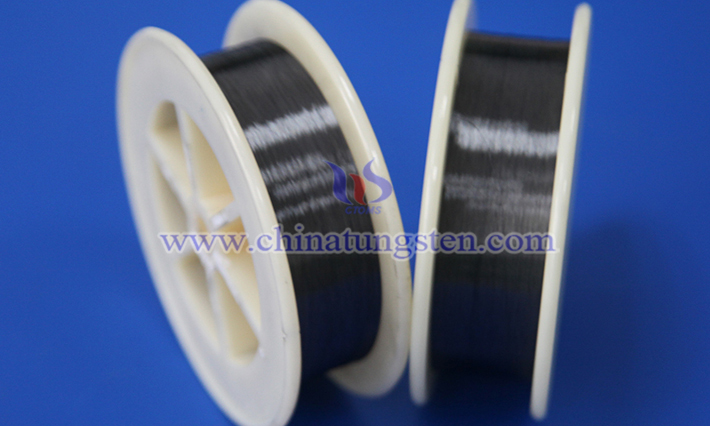

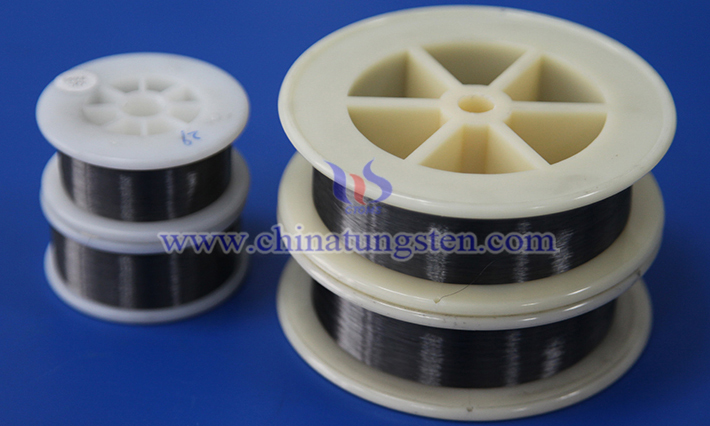

Tungsten wire (tungsten metal) has extremely high hardness and wear resistance, and adding it to the glove material can significantly improve the cut resistance. This type of glove can usually achieve a higher level of protection (such as level 5 or higher in the EN388 standard), effectively preventing cutting by knives, sharp metals or other sharp objects.

2. Wear Resistance and Durability

The addition of tungsten wire makes the gloves not only cut-resistant, but also resistant to friction and wear, with a long service life, suitable for long-term high-intensity use.

3. Flexibility and Comfort

Although tungsten wire is tough, high-quality cut-resistant gloves are combined with other soft materials (such as high-performance polyethylene fiber, glass fiber or aramid fiber) to ensure that the gloves are both protective and flexible for delicate tasks.

4. High Temperature Resistance

Tungsten has an extremely high melting point (about 3422°C), so these gloves can usually withstand a certain degree of high temperature and are suitable for work environments involving heat sources or sparks.

5. Breathability and Ergonomic Design

Modern cut-resistant tungsten wire gloves often optimize breathability and fit to avoid excessive sweating or fatigue on the hands and improve the wearing experience.

6. Multifunctional Protection

In addition to cut resistance, some styles also have puncture resistance, anti-slip or chemical corrosion resistance, depending on the compound material and design of the gloves.

If you are interested in cut-resistant tungsten wire, please feel free to contact CTIA GROUP: sales@chinatungsten.com.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com