Ultrasensitive WO3 Gas Sensors for Nitrogen Dioxide Detection in Low Oxygen Environment

- Details

- Category: Tungsten Information

- Published on Friday, 22 October 2021 22:27

Gas sensing at room temperature has attracted a lot of research interest, especially the combination of MOX, CNT and graphene, but it usually has the problems of slow response time, poor baseline stability, and high humidity dependence.

Several types of nitrogen dioxide (NO2) gas sensors have been developed and commercialized, including metal oxide semiconductors and solid electrolytes. Among metal oxide semiconductors, tungsten trioxide (WO3)-based semiconductors have received special attention due to their simple structure, high sensitivity, low cost, and potential durability under extreme conditions. Ultrasensitive WO3 gas sensors for nitrogen dioxide detection in low oxygen environment has been prepared successfully, the resistive gas sensors not only had a high sensitivity to NO2 (3.4%/ppb vs. 0.2%/ppb obtained for commercial MOX) but can still operate reliably at lower oxygen levels (down to 0.5%). The preparation process is as below:

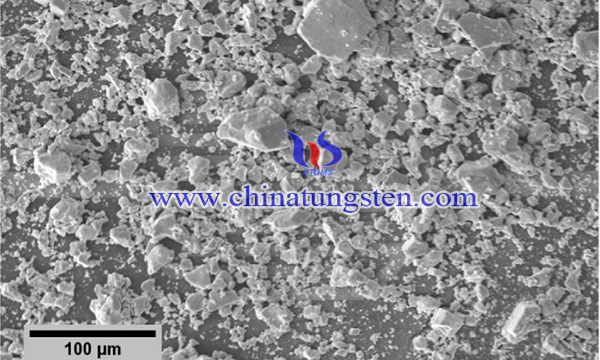

WO3 powder is mixed with the organic dispersant ESL 400 to obtain a paste. The weight ratio of powder to organic dispersant is 1:2. The paste is dropped onto a 1 mm x 1 mm silicon chip, which consists of gold interdigitated electrodes on the top of the film, as a single chip solution. After depositing the WO3 paste, the substrate was dried in air at room temperature for about 12 hours, then annealed at 450°C for 1 hour, and then annealed in ambient air at 350°C for about 23 hours to obtain a sensor element. Composition of n-type WO3. Figure 1(c) shows a scanning electron micrograph of an annealed slurry with a porous microstructure, showing a wide particle size distribution with an average diameter of several hundred nanometers. Finally, wire bond the silicon chip to a standard TO-46 connector.

In conclusion, ultrasensitive WO3 gas sensors for nitrogen dioxide detection in low oxygen environment has been prepared successfully. It was found that the resistive gas sensors not only had a high sensitivity to NO2 (3.4%/ppb vs. 0.2%/ppb obtained for commercial MOX) but can still operate reliably at lower oxygen levels (down to 0.5%). It was found that these sensors with the active layer prepared by drop casting and annealing work reliably at low oxygen levels with again a high gas sensitivity but with longer response and recovery times (20% or so).

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com