WO3/SiO2 Catalyst for Aromatic Nitration

- Details

- Category: Tungsten Information

- Published on Thursday, 23 September 2021 09:47

Aromatic nitration has long been an important process in industrial chemistry, because nitroaromatic products are widely used as dyes, pesticides, solvents, drugs, and intermediates for the manufacture of synthetic dyes and other chemicals. Traditionally nitration is carried out by using mixture of concentrated nitric acid (98%) and sulphuric acid in the proportion of 1:2. However the process produces large quantity of dilute sulphuric acid which leads to environmental pollution.

Thus, it is important to find a green nitration process. Solid acid catalyst is a promising method for nitration. Tungsten trioxide (WO3) is an n-type transition metal oxide and is a likely candidate for several applications such as electrochromic devices, smart window, microelectronics, gas sensors, supercapacitor, etc.

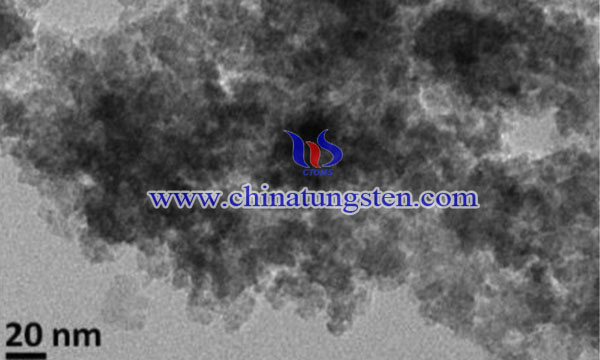

Thus, Silicon dioxide (SiO2) has been doped on WO3 to enhance its hydrophobicity of the catalyst. WO3/SiO2 catalyst synthesized using sol gel method has shown promising activity (up to 65% conversion) for aromatic nitration in liquid phase using commercial nitric acid (70%) as nitrating agent without using any sulfuric acid. The synthesis of WO3/SiO2 catalyst is as follows:

Ammonium metatungstate (10.62 g) was dissolved in 20 mL of distilled water and added dropwise to ethyl silicate 40 (100 g) in anhydrous IPA (70 mL) solution under constant stirring. Dilute further. NH4OH (2.5%) solution (6 mL) was added to the above solution and stirred until a white gel was obtained. The resulting gel was dried in air and then calcined in a muffle furnace at 500 °C for 5 hours.

Disperse 5.0 g of calcined 20% WO3/SiO2 in 25 mL of anhydrous toluene, to which 0.265 g, 0.08 g and 0.4 g Dynasylan 9896 (6.6 wt%, 2 wt% and 20 wt%) Dynasylan 9896 were added respectively. Then, the resulting mixture was heated at 80 °C while continuing to mix on a rotary evaporator for 8 hours. The toluene was then evaporated in vacuo and the resulting powder was dried in an oven at 100°C for 5 hours.

In summary, WO3/SiO2 catalyst synthesized using sol gel method has shown promising activity (up to 65% conversion) for aromatic nitration in liquid phase using commercial nitric acid (70%) as nitrating agent without using any sulfuric acid. Since benzene forms an azeotrope with water at a lower temperature, the catalyst can be effectively recycled for benzene nitration without the use of additional solvents, so that water can be easily removed from the reaction system.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com