W/TiC Nanocomposites Prepared with Ammonium Paratungstate for Various Applications

- Details

- Category: Tungsten Information

- Published on Thursday, 08 July 2021 05:24

Tungsten and its alloys are primary candidate materials in fusion reactors (international thermonuclear experimental reactor and the future demonstration power plant reactor) because of their high melting point, high thermal conductivity, high strength at elevated temperatures, low sputtering yield in radiation environment and low tritium inventory. Unfortunately, tungsten and its alloys have the drawbacks of low-temperature brittleness, high-temperature brittleness, and low recrystallization.

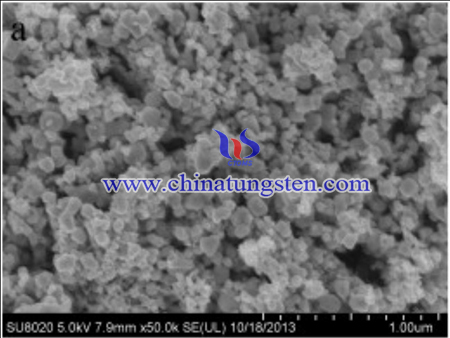

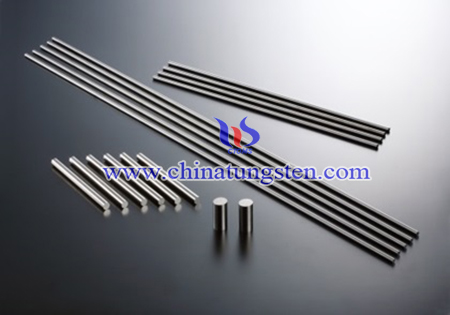

Novel sintering techniques, including microwave sintering, hot isostatic pressing (HIP), and spark plasma sintering (SPS), have recently been used to prepare fine-grained and dense materials. Thus, W/TiC nanocomposites have been prepared with ammonium paratungstate as raw material, the result shows a high thermal stability at high temperature.

The synthesis process of W/TiC composites is as following steps: Appropriate amount of oxalic acid (C2H2O4·2H2O) was dissolved in deionized water to form a clear solution, the 1.0 wt.% nano-sized TiC particles was added into the solution. The amount of TiC nano-particles was calculated by stoichiometry.

Ammonium paratungstate (NH4)10H2W12O42·XH2O (APT) was dissolved in the above solution of oxalic acid with TiC powder. The W/TiC precursor was obtained by stirring and evaporating the mixture solution in a methyl silicone oil bath at 165 °C. The precursor was ground and then heated in a tubular furnace reduced by high-purity hydrogen in a tubular furnace at a heating rate of 5 °C/min. The heating temperature profile was raised to 200, 500 and 800 °C, and isothermal for 30, 60 and 60 min respectively. The samples were left in the furnace to cool down to room temperature at the same rate of 5 °C/min under hydrogen flow. The reduced W/TiC powder was consolidated using SPS (FCT Group, SE-607, Germany). The powder is loaded in an electrically and thermally conductive graphite die with a diameter of approximately 20 mm, and then a DC current is applied in pulses and assisted with a uniaxial high mechanical pressure during the process.

In conclusion, W/TiC nanocomposites have been prepared with ammonium paratungstate as raw material, the result shows a high thermal stability at high temperature. After sintering, the relative density of W/TiC alloy could reach to 99.0%. Doped TiC nanoparticles were detected at the grain interior and grain boundary. the W/TiC alloy possess high thermal stability at high temperature.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com