Synthesis of High-Purity Tungsten Powder with APT for Application in HID Lamps

- Details

- Category: Tungsten Information

- Published on Thursday, 08 July 2021 05:13

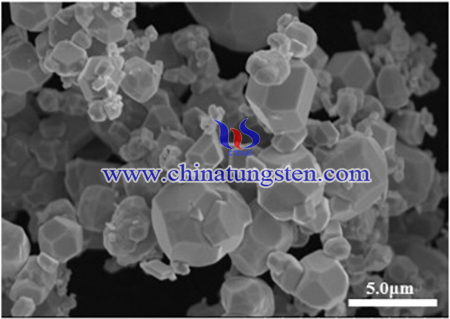

Ultra-high purity tungsten (W) (W > 99.9999 wt.%) powder is an important raw material in lighting industries for manufacturing high performance electrodes for high intensity discharge (HID) lamps to avoid outgassing impurities and thus guarantees a consistent lamp quality and increased lifetimes. Unfortunately, the common process for preparing high-purity W powder has the drawbacks of low efficiency, high cost, and high energy consumptions. In order to get over these disadvantages, synthesis of high purity tungsten powder have been successfully conducted with APT for application in HID lamps.

Ammonium paratungstate (APT) with different purity depending on the uranium (U) and thorium (Th) contents had been used as precursor material. APT with low U or Th concentration was produced by leaching under atmosphere pressure, extraction and crystallization, which was further purified by double or multiple crystallizations to remove other impurities. The process is more efficient and suitable for mass production, compared to the conventional technology including high pressure autoclave, ion exchange and crystallization. The main impurities in primary and purified APT were analyzed by atomic absorption spectrometry (AAS), inductively coupled plasma optical emission spectrometry (ICP-OES) and colorimetric method. The obtained purified APT was reduced by hydrogen (H2) in a single step under clean room condition to W powder of high purity.

Two types of high purity W material for electrodes in HID were prepared. One was W rod with diameters in the range of 12–40 mm, which was processed by powder compaction with cold isostatic pressing (CIP), sintering at a temperature higher than 2000 °C in an induction heating furnace under a H2 protection atmosphere, and hot forging. The other one was W wire with diameters in the range of 0.02–12 mm, which was fabricated by powder compaction by CIP, self-resistance sintering at approximately 2700–2800 °C, swaging and wire drawing.

In summary, the cost-effective process for producing high-purity W powder has been prepared using APT. 5N and 6N W rods and wires. As important electrode materials for high performance HID lamps, have been fabricated with conventional powder metallurgy and hot deformation processes.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com