Synthesis of Ca3WO6 for Cleaner APT Production

- Details

- Category: Tungsten Information

- Published on Monday, 05 July 2021 14:56

The manufacture process of ammonium paratungstate (APT) by treating tungsten concentrates at present can be divided into acidic leaching method, soda or caustic soda leaching method and ammonium salt leaching method. The former two methods are conventional processes, in which the tungstic acid or sodium tungstate obtained need to be transformed into ammonium tungstate for producing APT, therefor there are a great amount of wastewater together with a plenty of auxiliary materials consumption due to difficult recycling of leaching reagents. The ammonium salt leaching method can directly obtain ammonium tungstate solution and thus has drawn great attention. It is of great significance to search a cheap and easily-cycled ammonium salt as leaching reagent to produce APT cleanly and efficiently.

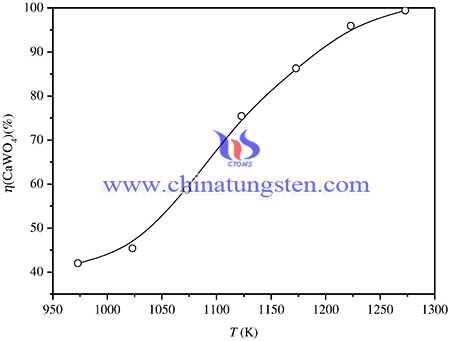

Ammonium carbonate is a widely used industrial material with low price and a considerable solubility in water. Ca3WO6 have been synthesized from tungsten-containing materials for cleaner APT production, the as-synthesized Ca3WO6 clinker has good leachability in aqueous ammonium carbonate solution with WO3 recovery of 98.4%.

The synthesis process of is as following steps: The reagents used in this work were analytically pure, lime was prepared from calcium hydroxide by roasting at 1273 K for 2.0 h. Artificial scheelite was first precipitated by the reaction of sodium tungstate solution and calcium chloride solution [19], the obtained precipitate was then washed, dried and calcined at 1273 K for 2.0 h. The scheelite concentrate and natural mixed concentrate of scheelite and wolframite.

The starting materials were crushed and ground to granularity with size minus 74 μm, and then raw meal was prepared by following two methods: (1) Mixing. In order to obtain well-mixed raw meal, the ground tungsten-bearing raw material and calcium compound (CaO, Ca(OH)2 or CaCO3) were mixed in a certain proportion by a mineral mixer for 24 h with particle size less than 45 μm of 72.21% (volume) in raw meal (by Mastersizer 2000, Malvern Instruments Ltd.); and (2) Milling. The raw meal prepared by method 1 was milled by vibrating mill for 9 min with particle size less than 45 μm of 98.79%.

20 g raw meal was put in a corundum crucible and then roasted in a thermostatic muffle furnace at preset temperatures in air for certain duration, the resultant was subsequently taken out from the furnace and cooled naturally in air to room temperature.

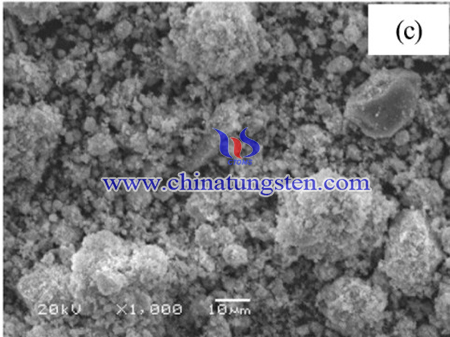

The cooled clinker was ground by vibrating mill to the granularity with particle size minus 74 μm, and then 20 g ground clinker was leached by 100 mL aqueous ammonium carbonate solution in a 150 mL sealed rotating steel reactor immersed in glycerol cell with a preset temperature. Two 15 mm-diameter and two 5 mm-diameter steel balls were added into the reactor in order to strengthen stirring.

In summary, Ca3WO6 have been synthesized from tungsten-containing materials for cleaner APT production, the as-synthesized Ca3WO6 clinker has good leachability in aqueous ammonium carbonate solution with WO3 recovery of 98.4%. Increasing roasting temperature not only accelerates the conversion of CaWO4 to Ca3WO6 but also eliminates the dependence of the conversion on calcium compound types. The synthesis method is feasible to recycle both auxiliary materials and solutions for cleaner production of ammonium paratungstate.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com