WC–Ni Nanostructured Composite Powders From Ammonium Paratungstate and Nickel Nitrate

- Details

- Category: Tungsten Information

- Published on Monday, 25 January 2021 19:29

low thermal expansion, high hardness, low fracture toughness, excellent chemical stability and high melting point of the tungsten carbide-WC ceramic phase, along with excellent toughness properties in the ductile phase of the binding metal (Co, Ni, Ti or Fe), making it indispensable in applications in cutting tool industries and in drilling, drawing, extrusion, machining and forging processes.

In addition, they are also applied to mechanical seals, dies and compacting punches of metallic or ceramic powders, and oil drilling tools. However, the mechanical properties (hardness and resistance) of WC-Ni carbides are relatively lower than those of WC-Co cemented carbides. Nevertheless, improvements in the properties of these WC-Ni composites can be obtained through microstructural changes.

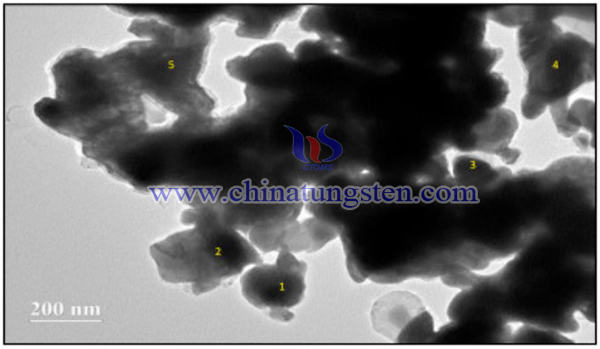

nanostructured WC-10 wt%Ni composite powders synthesized via carboreduction of an ammonium paratungstate and nickel nitrate mixture in order to study the morphology and structure of these composite powders,

The synthesis process can be concluded as below:

Firstly, nickel nitrate hexahydrate (Ni(NO3)2·6H2O, 99%) and ammonium paratungstate (99%) were used as starting materials. Precursors were initially mixed in a mortar with the aid of a pistil and dried in an oven at 150 °C for 24 h. Next, the dry powders (2 g) were macerated and heat treated at 850 °C/2 h in an atmosphere consisting of a mixture of CH4/H2 (5%/95%) with a flow rate of 20 L/h through a fixed bed reactor and a heating rate of 10 °C.min−1.

Then, the synthesized WC-10 wt%Ni powder was placed in a graphite mold and sintered in the form of a 5 mm diameter disk using DR SINTER LAB Jr. equipment (SPS 211 LX Model). Next, the parameters were programmed and executed. The samples were sintered at 1350 and 1450 °C under pressure of 20 MPa, a heating rate of 215 °C, and isothermal level of 10 min. The system was cooled freely, relieving uniaxial pressure and shutting off the electrical current supply. The residual graphite layer from the sintering process was removed through metallographic procedures (sanding and polishing).

Vickers hardness measurements were performed on the microstructure of the cutting section according to the ASTM 092 standard, and using PANTEC RBS 65 equipment. The measurements were conducted under the conditions of six indentations and an applied load of 30 Kgf for 6 s. The theoretical density of the WC-10 wt%Ni composite was determined by the mixtures rule, which considered the WC and Ni theoretical densities of 15.7 g/cm3 and 8.91 g/cm3, respectively. The relative density of the sintered compacts was determined by the pycnometer method for solids at room temperature (25 °C) using ethyl alcohol (0.791 g/cm3).

In conclusion, WC-10 wt% Ni composite powders with a high degree of purity, good crystallinity and crystallite size in nanometric order for the 24 nm WC, formed by agglomerated particles with heterogeneous distribution and size. good densification and an excellent hardness to the sintered composite at 1350 °C by making the binder layers which cover the tungsten carbide particles into an excellent lubricant.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com