Tungsten Composite Material with High Shock Thermal Resistance from Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Monday, 25 January 2021 02:36

In nuclear fusion reactors, plasma facing materials (PFMs) are inevitably impacted by a series of particle flows and accompanying energy flows. Due to the favorable physical properties under particle flows and heat load, tungsten and tungsten-based materials are considered the most promising PFMs. Under the condition of fusion service environment, tungsten and its composites suffer low energy (tens of eV to several KeV) and high flux (up to 1022–1024m−2s−1) hydrogen-helium plasma-irradiation damage, resulting in performance degradation and shortened service time seriously affecting the safety and reliability of fusion devices

Thus, a tungsten-based material with high shock thermal resistance is in need. was selected as the second-phase particle. A W–Y2O3 composite materials has been produced through wet chemical method to achieve the distribution of the second-phase particles in the grain interior and improve the structures and properties, the following adaptation of rolling method improves the performance of the material.

The preparation process is as below:

Ammonium paratungstate (≥ 99.95%) and yttrium nitrate hexahydrate (Y(NO3)3∙6H2O, ≥ 99.5%) were selected as raw materials for W and Y2O3, respectively, and oxalic acid (C2H2O4∙2H2O) was selected as the precipitant to obtain the W–Y2O3 precursor.

The W–Y2O3 precursor was reduced in H2 atmosphere to obtain the W–2%Vol Y2O3 composite powder. The W–2%Vol Y2O3 composite powder was pressed by cold isostatic pressing. Then, it was placed in a conventional high-temperature sintering furnace and sintered at 2573 K in H2 atmosphere for 6 h. The resulting W–Y2O3 billet was hot-rolled at 1853 K for further densification and microstructure improvement. W–Y2O3 composite material with a rolling ratio of 50% were obtained. That is, the thickness of the material along the normal direction (ND) after rolling is half of its original thickness. For the contrast experiment, pure tungsten has a purity over 99.95%. The rolling ratio of the pure tungsten was 50%.

The pure tungsten and W–Y2O3 composite material were annealed at 1373 K for 1 h for the elimination of intrinsic defects and internal residual stress. The pure tungsten and W–Y2O3 composite material were cut into 1 mm-thick squares (10 mm × 10 mm). The surfaces were mechanically polished. Surface roughness (Sa) of the polished surfaces was calculated using a confocal laser scanning microscope (CLSM, OLS4100, Japan). Surface roughness value (Sa) is 0.138 μm the area scanned on the sample is 2.56 × 2.56 mm2.

The laser thermal shock experiment was performed in Ar atmosphere, which was sprayed from the source of the laser beam gun and mainly covered the center zone. The gas flow rate was 10 L/min. The energy distribution of the laser beam was Gaussian distribution. The laser scanning frequency was 5 Hz, the laser spot diameter was 0.3 mm, the scan time was 1 ms, the laser current was 60 A, and the average power density of the corresponding laser beam was 21.0 MW/m2, but the power density of the laser beam at the impact center zone was more than 21.0 MW/m2.

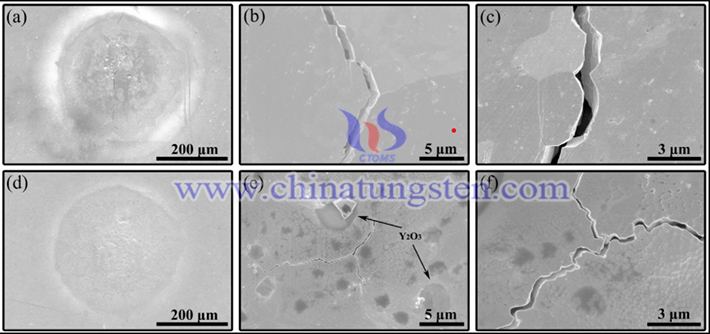

In summary, W–Y2O3 composite material have a higher resistance to laser thermal shock than pure tungsten. Additionally, cracks in these materials were generated and propagated easily along the direction of grain elongation. After helium ion irradiation, the cracking caused by laser thermal shock was dominated by intergranular cracks.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com