Porous Silicon Composite One-Dimensional Tungsten Oxide Nanostructured Gas Sensitive Materials

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 17:51

Nitrogen oxide (NOx), as a highly toxic gas, is the main source of acid rain and photochemical smog, which has posed a serious threat to human health and safety. Therefore, the detection of nitrogen oxides has become a research hotspot in recent years.

One-dimensional tungsten oxide nanostructure is used as gas-sensing material by scientists and technicians. It has huge specific surface area and large surface activity. It provides a large number of gas adsorption sites and diffusion channels. It overcomes the shortcomings of high working temperature based on tungsten oxide gas-sensing material, and develops a kind of gas-sensing material at lower temperature (100 C). Silicon-based one-dimensional tungsten oxide nanostructured gas sensor elements with high sensitivity and fast response/recovery rate are synthesized.

1) Cleaning silicon substrate:

A 2-inch P-shaped single-side polished silicon wafer with a resistivity of 10_.cm and a thickness of 400 um, (100) crystal orientation was cut into rectangular silicon substrates with a size of 2.4 cm *0.9 cm. The silicon wafers were immersed in concentrated sulfuric acid and hydrogen peroxide solution for 30 minutes, hydrofluoric acid solution for 20 minutes, acetone solvent for 15 minutes, anhydrous ethanol for 15 minutes and deionized water for 10 minutes respectively.

2) Fabrication of ordered porous silicon with micron-sized channels on silicon substrate:

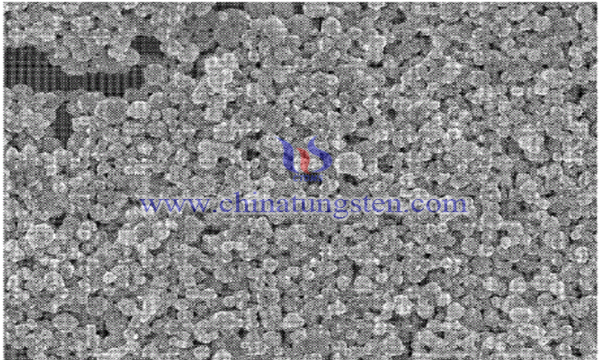

Porous silicon layer was prepared on polished surface of silicon wafer by double cell electrochemical method. The corrosion electrolyte consists of hydrofluoric acid with 40% mass concentration and dimethylformamide with 40% mass concentration. The volume ratio is 1:2. No surfactant and additional light are added. The applied corrosion current density is 60 mA/cm2 and the corrosion time is 10 min. The porous silicon formation area is 1.6 cm x 0.4 cm. According to the results of scanning electron microscopy (SEM) analysis of surface morphology and profile structure of ordered porous silicon with micron-size pore, the average pore diameter and thickness were 1.5 and 10 microns respectively.

3) Fabrication of porous silicon-based one-dimensional tungsten oxide nanowires:

Put 5g tungsten powder in the alumina ceramic boat and place it in the center of the constant temperature zone of the horizontal tubular furnace; place porous silicon produced in step (2) at the direction of the outlet of the tubular furnace 16 cm away from the alumina ceramic boat; vacuum in the furnace after 20 minutes of entering the argon cleaning furnace, vacuum in the furnace is 5Pa, and mixed gas with 99.999% argon and 99.999% oxygen of the mass purity is introduced. The gas flow rate is divided into two parts. Do not adjust the gas valve for 5sccm and 0.5sccm, keep the pressure in the furnace 57Pa. At 30 degree /min, the temperature is heated to 1100 degrees centigrade, after constant temperature 90min, and the gas tungsten oxide nanowire composite structure is obtained by decreasing the temperature in the mixed gas atmosphere to room temperature. One-dimensional tungsten oxide nanowires are 40-60 nm in diameter and 20-30 um in length.

4)Fabrication of porous silicon-based tungsten oxide nanowires composite structure gas sensor element: The porous silicon-based one-dimensional tungsten oxide nanowires prepared in step (3) were placed in the vacuum chamber of DPS-III ultra-high vacuum magnetron sputtering equipment. The background vacuum is 4.5 *10-4Pa, the metal platinum with 99.95% mass purity is used as target material, the argon with 99.999% mass purity is used as working gas, the flow rate of argon gas is 24 sccm, the sputtering pressure is 2.0Pa, the sputtering power is 90 W, the sputtering time is 8 min, the substrate temperature is room temperature, and a pair of square platinum electrodes with the size of 0.2cm *0.2cm are sputtered on the surface of tungsten oxide nanowires with the spacing between the electrodes. The gas sensor element is 0.8cm.

Porous silicon composite one-dimensional tungsten oxide nanostructured gas sensing materials can easily react with gases because of their large specific surface area and surface activity, which can provide a large number of gas adsorption sites and gas diffusion channels. Porous silicon-based one-dimensional tungsten oxide nanostructured gas sensor has high response value and good selectivity to low concentration of nitrogen oxides gas at low temperature, short response/recovery time, compact size, simple structure, mature fabrication process, convenient use and low cost, which is expected to be popularized and applied in the field of gas sensors.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com