Synthesis of Zinc and Cadmium Tungstate Nanocrystals by Mechanical Alloying

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 September 2019 23:07

Nano-semiconductor materials have been widely studied and applied due to their excellent properties such as quantum size effect, surface effect and unique optical properties. Tungstate, as an important oxide semiconductor, has been widely studied and applied in recent years.

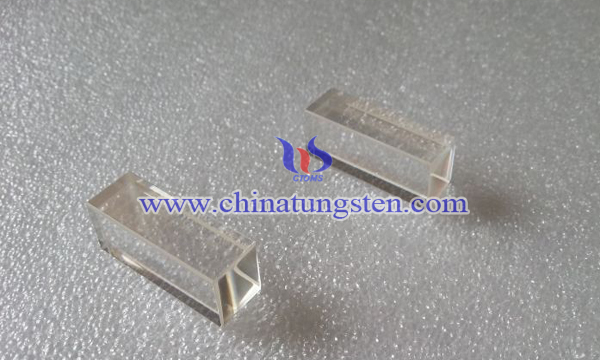

Zinc tungstate belongs to monoclinic system and [WO6] octahedron in zinc WO4 is the center of luminescence. It belongs to intrinsic luminescence. It is a good scintillating material. Zinc tungstate single crystal is widely used in X-ray tomography, geophysical prospecting and high energy particle detection. Cadmium tungstate and zinc tungstate have the same structure and similar characteristics. The solid solution of Zn1-xCdxWO4 formed by solid solution of ZnWO4 and CdWO4 has the advantages of adjustable energy gap, which is better in photocatalytic degradation and as scintillating material. At present, hydrothermal synthesis and other wet chemical methods are the main methods to synthesize tungstate. However, this method is troublesome, energy-consuming and low-yield. So researchers try to synthesize zinc-cadmium tungstate nanocrystals by mechanical alloying. Its process includes:

Zinc oxide, CdO and WO3 powders were weighed in the ratio of 0.5:0.5:1 by massage. The error of weighing was kept within the range of (+0.0002g). The particle size of the powders was 100 nm (+5 nm). The weighed samples were placed in ball mills with different diameters (2-12 mm) and sealed (ball-to-material ratio was 5:1). The powders were loaded in ball mills. Ball milling was carried out on the machine. Samples were taken and stored after 1 h, 2 h, 5 h, 10 h, 20 h and 30 h of ball milling respectively. In addition, the ratio of massage Erbi 1:0:1, 0.8:0.2:1, 0.2:0.8:1 and 0:1:1 is used to weigh ZnO, CdO and WO3 powders respectively for 6 g. The error of weighing is kept within (+0.0002 g). The weighed samples are placed in ball mills with different diameters (2-12 mm) and sealed (ball-to-material ratio is 5:1) and loaded in ball mills. Ball milling was carried out on the machine. Samples were taken and stored after 30 hours of ball milling.

The prepared Zn1-xCdxWO4 nanocrystals have uniform chemical composition, single structure and no impurities on the surface, which can show the intrinsic physical properties of the materials well. Because of its good optical properties and adjustable energy gap, it can be better used as scintillating materials, photoluminescent materials and photocatalytic materials.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com