One-step Hydrothermal Method of Tungsten Oxide Quantum Dots and Tungsten Oxide Nanowires

- Details

- Category: Tungsten Information

- Published on Monday, 23 September 2019 22:20

Tungsten oxide is a kind of tungstic anhydride and a kind of tungstate product. Tungsten oxide includes trioxide and tungsten dioxide. Tungsten oxide is partly used in the production of chemical products, such as paints and coatings, petroleum industrial catalysts, etc. But tungsten oxide is more an intermediate product and is widely used in the preparation of tungsten metal powder and tungsten carbide powder. It is used in the production of tungsten metal products and a large number of tungsten alloy products.

In the existing technology, tungsten oxide quantum dots are synthesized by using tungsten hexachloride or tungstate as tungsten precursors in the presence of surfactants or polymers. However, after tungsten oxide quantum dots are synthesized, it is necessary to remove the template used in the synthesis process, but the operation process of removing the template is extremely complex. It is difficult to get rid of impurities, and the residual samples will have a negative impact on the properties and use of tungsten oxide quantum dots. Therefore, the preparation of tungsten oxide quantum dots by template method becomes more complex for further application.

In order to overcome the shortcomings of the existing technology, the researchers designed a simultaneous preparation method of tungsten oxide quantum dots and tungsten oxide nanowires by one-step hydrothermal method. Its implementation includes:

(1)First, 0.0667 g tungsten hexachloride was dissolved in 12 ml absolute ethanol, and golden clarified tungsten hexachloride ethanol solution was obtained after stirring.

(2)Transfer the solution prepared in step (1) into the sealed polytetrafluoroethylene tank and place it in the hydrothermal reactor. The hydrothermal solution is prepared by hydrothermal treatment for 4-10 hours at the temperature range of 120-220 ℃. The solution includes tungsten oxide quantum dots, tungsten oxide nanowires, ethanol reactants and water. The ethanol reactants include ether, ethanol, hydrogen chloride and a small amount of water;

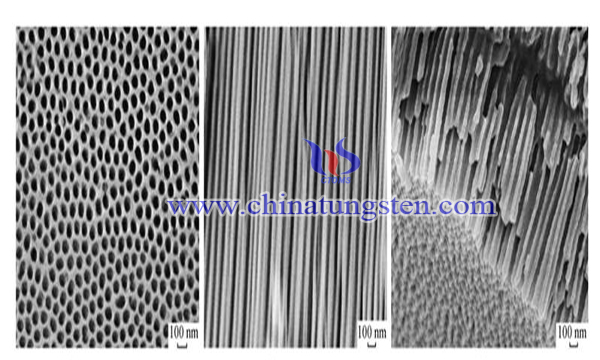

(3)When the solution after hydrothermal treatment is naturally reduced to room temperature, the PTFE tank in the hydrothermal reactor is taken out and the solution in the PTFE tank is taken out and put into the centrifugal tube. The centrifugal tube is symmetrically placed in the centrifuge and centrifuged for more than 10 minutes at a speed greater than 10,000 rpm. The centrifugal solution after centrifugation is prepared and separated. The supernatant consists of tungsten oxide quantum dots (TQDs) and ethanol reactants in the supernatant, and the precipitation in the lower layer is tungsten oxide nanowires.

(4)The supernatant of the centrifugal solution prepared in step (3) was dialyzed in a dialysis bag with a molecular weight of 500 for 24 hours, then ether, ethanol and hydrogen chloride were removed by dialysis to produce pure tungsten oxide quantum dot solution.

(5)Take the precipitation in step (3) and wash it with deionized water for 6 times, remove the impurities attached to the surface, then freeze-dry the precipitation below - 20 ℃ for more than 20 hours to prepare tungsten oxide nanowires.

Tungsten oxide quantum dots and nanowires were synthesized using tungsten hexachloride as the precursor of tungsten. Tungsten oxide nanowires were synthesized by hydrothermal action. Tungsten oxide quantum dots were formed by hydrothermal cutting method. Tungsten oxide quantum dots and tungsten oxide nanowires could be synthesized stably, reliably and efficiently at the same time. It is used in conventional applications of quantum dots such as fluorescence imaging and iron ion specific detection.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com