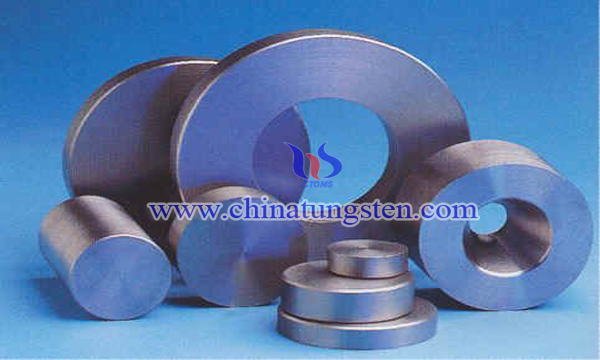

Tungsten Sintered Sputtering Target Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 08 September 2019 00:00

In recent years, with the high integration of super LSI, the use of materials with lower resistance as electrode materials or wiring materials has been studied. In such materials, high purity tungsten with low resistance, thermal and chemical stability is used as electrode materials or wiring materials.

A method for preparing tungsten sintered sputtering target has been proposed by some scholars.

Tungsten powder with purity of 99.999%, phosphorus content less than 0.1 weight ppm and average particle size of 0.6 um was filled into graphite mould. After sealing with the same material, the vacuum was reduced to 10-2 Pa. Then, the high-frequency current of 4000A is charged up and down for 10 minutes to generate plasma between the surface of tungsten powder, thus purifying and activating the surface of tungsten powder. Next, after stopping the power supply, the pressure of 30MPa is applied to the die, and the die is heated to 1800 ℃ by external heating for 2 hours.

The relative density of the sintered tungsten is 99.9%, and the average grain size is 30 um. No abnormal particle size is observed. In addition, the oxygen content is 3 ppm.

The results of sputtering using the sintered tungsten as target show that the powders on the film are 0.09/cm2. This may be attributed to the fact that there are no abnormal grains, so the number of powders decreases significantly.

The characteristics of tungsten sintered sputtering target are that the phosphorus content is less than 1 ppm by weight, and the rest are other unavoidable impurities and tungsten. When the phosphorus content is set below 1 ppm, the abnormal grain growth of tungsten can be effectively inhibited. It can prevent the decrease of target strength, solve the problems of tungsten sintered target at one stroke, such as the generation of unqualified target products, the reduction of target production rate and the rise of manufacturing cost, and improve the uniformity of tungsten wiring film.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com