Tungsten Chromium Cobalt Base Superalloy Powder for Spraying

- Details

- Category: Tungsten Information

- Published on Friday, 19 July 2019 23:32

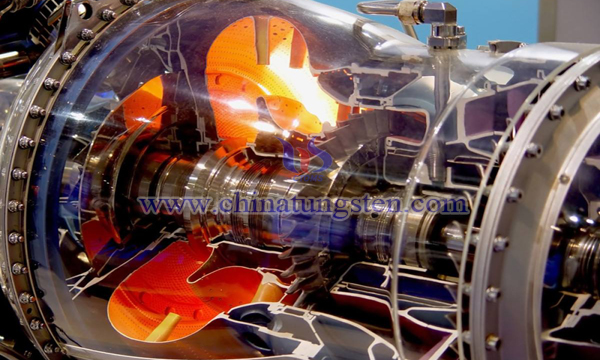

The coating material of turbine outer ring of engine, especially aeroengine, requires advanced high temperature resistance, oxidation resistance, thermal erosion resistance and good sealing performance. Tungsten chromium cobalt alloy powder is a kind of coating material which can be used as the bottom layer. It has good adhesion and bonding strength with titanium alloy and other superalloys. The structure of the coating is evenly distributed. There are no cracks, delamination and separation between the coating and the substrate. It is a good bottom layer material for spraying.

The preparation method of tungsten chromium cobalt base superalloy powder with wear-resistant coating on engine turbine outer ring can be carried out in the following steps:

According to the percentage of quality: Cr25.5-26%, Ni10-11.5%, W7-8%, C0.45-0.55%, O<400 ppm, the remaining amount is Co; the fineness of powder is less than 325 meshes, the fluidity is 22-24s/50g, and the pine ratio is 4.3-4.8g/cm3.

(1)According to the quality percentage of chemical composition Cr25.5-26%, Ni10-11.5%, W7-8%, C0.5-0.55% and the remaining amount of Co, vacuum smelting is carried out in medium frequency induction furnace with vacuum degree less than 10Pa. When feeding, nickel plate and part of cobalt are placed at the bottom of the furnace, tungsten bar and metal chromium are put in the middle of the furnace, and the remaining cobalt plate is put on the top. Under the protection of inert gas, the alloy liquid is obtained by melting.

(2)The alloy liquid is atomized into the atomizing tank through tundish and diversion tube. The diameter of the diversion tube is 8mm, the vacuum degree in the atomizing tank is less than 2Pa, the atomizing temperature is 1500-1700 ℃, the retractable annular slot nozzle is selected as the atomizing nozzle, and the top angle of the atomizing nozzle is 30-60 degrees. Inert gas or nitrogen gas is sprayed to atomize the alloy liquid, and the atomizing pressure is obtained. The atomized powder is 0.6-3 MPa. The powder is separated by cyclone in the collector under the atomizing tank and enriched in the cyclone dust collector. The tungsten chromium cobalt base superalloy powder base superalloy powder is obtained.

The obtained tungsten chromium cobalt base superalloy powder has smooth spherical micro-morphology, flowability is 22-24s/50g, pine ratio is 4.3-4.8g/cm3, oxygen content is less than 400 ppm. When it is coated by supersonic spraying process, the application requirements of wear-resistant coating for engine turbine outer ring are fully met.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com