A New Preparation Process of Tungsten Nanowhiskers

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 July 2019 01:22

Nanowhiskers, nanowires and nanorods are nearly perfect materials, which have superior performance compared with metal materials. As a structural material, tungsten whiskers or tungsten nanowires are used to reinforce and toughen refractory alloys, ceramic materials, etc. Can significantly enhance the toughness and strength of the material.

In addition, tungsten nanowhiskers have excellent field emission properties and gas ionization properties, and can be used to fabricate field emission appliances, flat panel displays, and gas ionizers, such as nanoscale tungsten probes, which are lithography machines and chips. One of the important components of a manufacturing machine.

The following technical solutions can be adopted for the preparation of tungsten nanowhiskers:

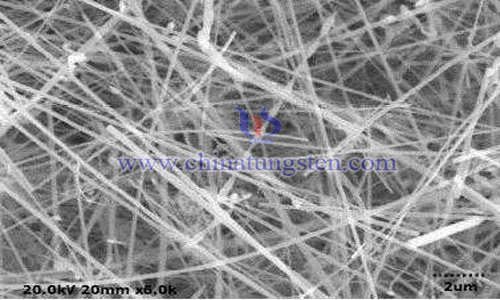

Weigh 200g of pure tungsten powder, the tungsten powder has a particle size of 2~5μm, and arrange 7wt% of nickel and iron metal powder, and mix by ball milling. The effect of mixing nickel and iron metal powders is to induce the growth of tungsten whiskers. Take 2.0g of mixed powder, tiling in the cleaned stainless-steel boat, push the stainless-steel boat into the tube-type reduction furnace with inner diameter of 60mm, ensure that the stainless-steel boat is placed in the high temperature center of the reduction furnace, close the furnace door, and pass nitrogen gas. And hydrogen. The N2 flow rate was 0.3 L/min, the H2 flow rate was 0.03 L/min, and nitrogen gas was introduced into the furnace through a three-necked flask to which deionized water was added, and the three-necked flask was placed in an electric heating jacket. The reduction furnace was heated at a rate of 3 ° C / min to raise the furnace from room temperature to 500 ° C. Turn on the electric heating power supply and set the temperature at 80 °C to slowly increase the deionized water to 80 °C (this temperature controls the water vapor flow rate). The furnace temperature was raised from 500 ° C to 800 ° C at a heating rate of 2 ° C / min, and then held for 6 hours. After the reaction is completed, the furnace temperature is lowered to room temperature, and the product is opened to remove the product. After washing, filtering and drying with ethanol, a uniformly distributed micro/nano tungsten whisker/wire/rod is obtained, and the product shape is good, and the whisker/rod length the aspect ratio is 5-200, wherein a small amount of tungsten nanowires having a diameter less than 100 nm and uniformly distributed can be seen.

The tungsten whisker prepared by the above process has a good shape, and can obtain tungsten nanowhiskers has an aspect ratio of 5 to 200, and a tungsten nanowire having a diameter of less than 100 nm and uniformly distributed. The process has low reaction temperature, short reaction time, easy control, high yield, good product shape and uniform distribution, and is a good mass production plan.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com