Tungsten-based Refractory Carbide Composites Preparation at Low Temperature

- Details

- Category: Tungsten Information

- Published on Sunday, 07 July 2019 17:45

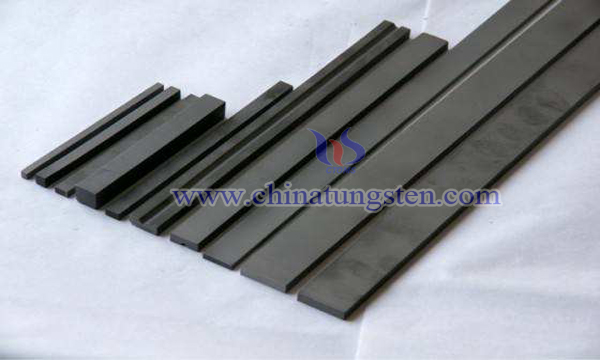

The composites composed of refractory metals and carbides are high temperature materials with excellent comprehensive properties. They make use of the complementary properties of materials to achieve comprehensive optimization. Tungsten-based refractory carbide composites are one of them. This kind of material has good thermal, chemical and mechanical compatibility, ideal high temperature strength and toughness, thermal shock resistance, ablation resistance and other excellent characteristics.

In order to solve the above problems, some researchers proposed a low temperature preparation method of tungsten-based refractory carbide composites, which is realized by the following steps:

1.93.4%-99.0% tungsten powder and 1.0%-6.6% carbon black were carbonized for 1-4 h at 1200-1600 ℃ by weight percentage, and incomplete carbonized tungsten carbide powders were obtained.

2.The incomplete carbonized tungsten carbide powders were prepared by adding 5wt.% polyvinyl alcohol aqueous solution, stirring for 2-4h, mixing evenly, then drying in the drying chamber at constant temperature. Among them, the 5wt.% polyvinyl alcohol aqueous solution added accounted for 5% of the quality of tungsten carbide powders.

3.The powder dried in step 2 is pre-pressed in the steel mould. The pressure is 10-20 MPa and the holding time is 3 minutes, so the green billet can be obtained.

4.The green billet obtained in step 3 is cold isostatic pressing and then pressure relief, in which the pressure is 50-200 MPa and the holding time is 2 minutes.

5.Porous tungsten carbide preforms were obtained by burning the green body after cold isostatic pressing for 2-4 hours in argon gas flow at 500 ℃ and then pre-burning for 2-4 hours in argon gas flow at 1500-1700 ℃.

6.The porous tungsten carbide preform alloys obtained in step 5 were infiltrated at 1200 ~1400 ℃ for 1-4 h to complete the preparation of tungsten-based refractory carbide composites.

Tungsten-based refractory carbide composites were prepared at 1200-1700 ℃. The theoretical calculation shows that the ratio of tungsten and refractory carbide in composites can be adjusted by adjusting the ratio of tungsten powder to carbon black, which can greatly improve the high temperature mechanical properties of composites, especially the thermal shock resistance and ablation resistance; the flexural strength of composites is 400-700 MPa, and the fracture toughness is 6-13 MPa m-1./ 2. The mechanical properties have been greatly improved.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com