Tungsten Carbide Coating Sprayed by Supersonic Flame

- Details

- Category: Tungsten Information

- Published on Thursday, 04 July 2019 21:46

The front and rear casings of the aero-engine compressor are made of iron-based and nickel-based alloys respectively. During the process of use, the butt joints of the front and rear casings are in vibration and are prone to impact wear. The original wear-resistant coatings are due to hardness. The lower the toughness, the more damage occurs after a period of wear, and the life of the front and rear casings is shortened. Therefore, it is an urgent problem to prepare a coating with high wear resistance to solve the wear of aviation equipment and prolong the service life of aviation equipment.

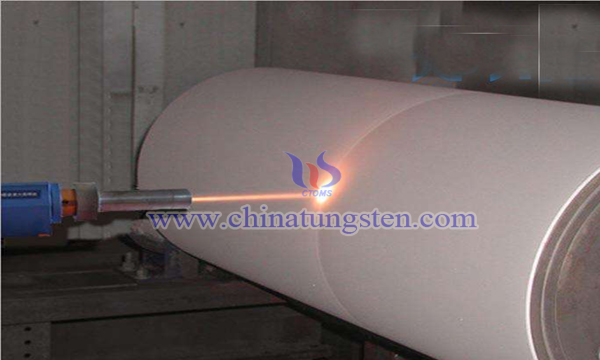

In the industry, tungsten carbide is an ideal coating material with high temperature resistance and wear resistance. Spraying a wear-resistant protective coating on the device can greatly improve its performance and service life. There are various technical options for preparing the coating. Including surfacing, thermal spraying, laser cladding, etc., for iron-nickel-based alloys, the most used is thermal spraying. For example, on a nickel-based forged alloy surface, a tungsten carbide coating can be applied by supersonic flame spraying. The process is as follows:

1.Dry tungsten carbide coated powder flat with a thickness of 10-30 mm, a drying temperature of 90-110 ℃ and a drying time of at least 2 hours.

2.Clean the surface of iron-based or nickel-based forged alloys with organic solvents, and then remove impurities such as oxide scales by sand blowing. The organic solvent is ethanol or acetone.

3.Fixed iron-based or nickel-based forged alloys and sprayed the above tungsten carbide coating powder onto the surface of iron-based or nickel-based forged alloys by supersonic flame spraying equipment. The spraying parameters are as follows: spraying distance 360-390 mm, powder feeding rate 65-80 g/min, gas pressure 3.5-4.0 bar, and wear-resistant coating is obtained.

4. Clean up the surface of iron-based or nickel-based forged alloys.

The powder compositions of the above tungsten carbide coatings are Co 15-19%, C 4.5-6%, Fe 0-2.5% and W by weight percentage.

Tungsten carbide wear-resistant coating sprayed by supersonic flame spraying is reliable and suitable for mass production. It can not only be used to coat the wear-resistant coating on the front and rear casing of aeroengine compressor, but also be applied to various types of ground gas turbine, energy, power and printing industries. The coating of components can effectively prolong the service life of components and has broad application prospects.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com