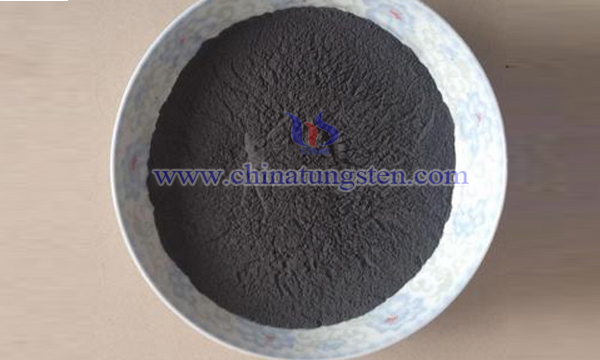

Spherical Single Crystal Tungsten Powder Preparation for Thermal Spraying

- Details

- Category: Tungsten Information

- Published on Tuesday, 14 May 2019 17:28

Thermal spraying using spherical single crystal tungsten powder to prepare thermal spraying technology is a rapidly developing surface strengthening technology. It uses special equipment, uses heat source to heat metal or non-metal materials to melt or semi-melt state, sprays them to the surface of the workpiece with high-speed airflow, forms coatings, and improves the wear resistance and corrosion resistance of the workpiece.

In order to meet the standards, modern industry has adopted a variety of processes to prepare spherical tungsten powder. For example, some scholars have innovated a preparation method of spherical single crystal tungsten powder for thermal spraying, which includes the following steps:

First, the ammonium tungstate solution with a mass concentration of 33% was weighed, and then a mixture of lithium carbonate and sodium chloride was added to the ammonium tungstate solution, which was evenly mixed and then dried and concentrated to prepare the precursor for reserve. The total amount of lithium carbonate and sodium chloride was 2 g/L, and the quality ratio of lithium carbonate and sodium chloride was 1:3.

Step 2. Spherical tungsten powder with grain size of 1 micron was selected as mother crystal and added to the precursor prepared in step 1 according to the quality ratio of 0.1%:1. The mixture was uniform and reserved.

Step 3. The mixture prepared in step 2 is reduced by hydrogen in a tubular reduction furnace. The flow rate of hydrogen is 40 ml/cm3 min, the reduction temperature is 900 ℃ and the holding time is 2 hours. After reduction, the mixture is cleaned by ultrasonic wave in deionized water. The ultrasonic power is 1500W and the cleaning time is 1 hour. Then the mixture is vacuum-dried at vacuum of - 0.06MPa and temperature of 80 ℃, drying for 1 hour;

Step 4. The spherical tungsten powder of 10-90 um was obtained by ball milling of the material treated in step 3.

Step 5. Spherical single crystal tungsten powders with fineness in the range of 20-63 um were obtained by air flow classification of the intermediate prepared in step 4 at the feed rate of 100 kg/h and the air flow rate of 1800 m3/h.

It is easy to grow tungsten powder grains by preparing precursors, to control the grain size and proportion of spherical single crystal mother crystals, to control the morphology and fine distribution of single crystal tungsten powder, and to control the sphericity and impurity content of powder without spheroidization of ball milling medium. The prepared spherical single crystal tungsten powder for thermal spraying has complete crystallization, compact particles, high sphericity, good fluidity, high purity, high hardness, high powder loading rate and low porosity.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com