Spherical Tungsten Powder Preparation by Plasma Arc

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 March 2019 21:32

Tungsten is an important strategic material, which is widely used in tungsten carbide tools, filaments, tool steel additives, rockets, space vehicles, nuclear reactors and other fields.

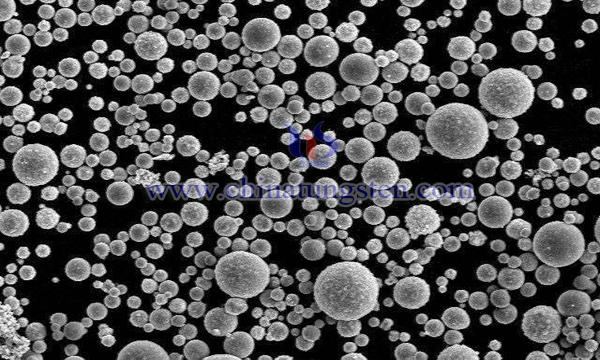

Plasma arc is a new type of heat source developed in the 1930s. After decades of development, it has become a perfect technology and widely used in industrial production. The plasma torch of high frequency is very pure because of no electrodes, and its plasma gas flow rate is small, heating efficiency is high. It is especially suitable for preparing ultrafine powder with high purity, small particle size and uniform particle size distribution. The preparation of ultrafine spherical tungsten powder by this method needs the following process:

By adjusting plasma parameters, the output power of high frequency machine is 33KW. Ar is used in both neutral and edge gas. The flow rate of middle gas is 2m3/h, the flow rate of edge gas is 5m3/h, the flow rate of H2 is 0.8m3/h, and the flow rate of NH3 is 0.8m3/h. A stable high frequency Ar+NH3+H2 mixed gas plasma is established. Using NH3 and H2 as carrier gas, raw material APT is added into the stable plasma arc. The APT particle size is 100um, and feeding. The quantity is 20g/min. The stainless steel sleeve in the cooling chamber is provided with reverse cooling water. The upper ventilation flange of the cooling chamber is tangentially supplied with cooling gas. The inlet temperature of the cooling water is 15 ℃. The cooling gas is Ar, and the flow rate is 6m3/h. The reaction time is 3 hours. After reduction, the product is protected by protective gas to prevent oxidation at high temperature. The protective gas used is inert gas, which does not need special passivation gas treatment. The ultrafine spherical tungsten powder was collected in the reclaimer after the reactor was cooled.

The advantages of high frequency Ar+NH3+H2 mixed gas plasma are that the arc cylinder is long and thick, the cylinder is full, the tail flame has no gap, and can run steadily for more than 2 hours without arc extinguishing. It is used to reduce ammonium paratungstate to prepare spherical nano-tungsten powder. Compared with ordinary high frequency Ar+H2 plasma, the shrinkage of the arc cylinder, the defect of the tail flame and the short reaction time are overcome. Compared with the traditional multi-step hydrogen reduction process of ammonium paratungstate, the product is not only spherical nano-tungsten powder, but also does not need calcination and other intermediate processes. The process flow is short, the production cycle is shortened, the operation is continuous and stable, the production efficiency is improved, and it is suitable for industrial production.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com